March 9, 2010 at 6:03 pm

March 9, 2010 at 6:03 pm

Forgive me for the probably stupid question, but i’ve always wondered something about the engines on commercial aircraft.

In the late 60’s and early 70’s airliners such as the 707, early incarnations of the 737 and DC-8’s to name a few, had really long engines or “missile type” engines as i call them. Why did the shapes change in the mid eighties?

By: Whiskey Delta - 7th April 2010 at 14:56

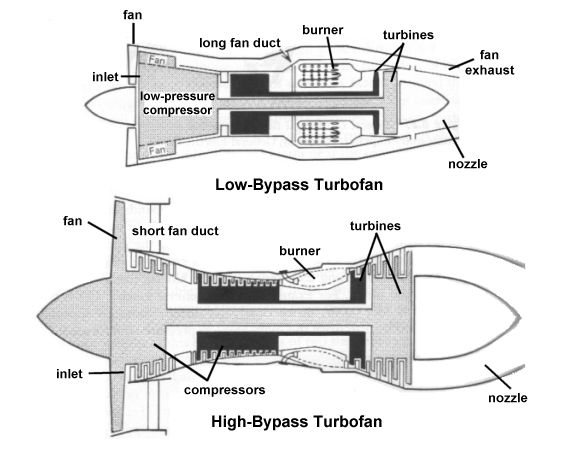

This shows the differences.

By: cammerguy - 6th April 2010 at 23:48

The “long engines” arent really longer than the high bypass engines the JT8’s on Conti A/C 211 are half tailpipe. With the high bypass engines the exhaust is far enough from the structure not to cause problems. Thanks for putting up that pic I’ve been with Conti for 23 years and I worked 211 way back when.

By: PBY-5A - 10th March 2010 at 01:55

Longshot – many thanks on that information. Interesting points.

By: longshot - 9th March 2010 at 23:08

Fatter looking modern engines

The posts so far have given the basic reason for the bigger diameter and fatter shape (a larger fan in the high by-pass engines).

On the attached 737 pics you see on the 1968 Britannia A/W shot with the original JT8D pod Joe Sutter decided to put under the wing of the 737 by moving a cardboard cut out engine around on a drawing till it looked right! But it created drag and Boeing had to supply the longer pod in your Continental photo to all operators (at Boeing’s expense, I suspect)

The second photo shows that later pod on a SudanAir gravel runway kit equipped 737…note the airjets to counteract the ‘hoover’ effect and the nosewheel gravel deflector

Shoe horning the fatter CFM engine into the 737-300 (now ‘Classic) was achieved by mounting the whole engine further forward so the big fan could sit higher . I believe the 737NG has a slightly longer undercarriage making a rounder pod possible

If you go back to the 40s the first British engines were fatter looking than later engines because they had centrifugal compressors which had ducting on the circumference…. compare the Meteor engines with the axials on the Me262

By: PMN - 9th March 2010 at 23:00

PBY… Check your PMs. 🙂

By: PBY-5A - 9th March 2010 at 22:23

It is very nice, likewise with my Fender Jazz!

What equipment do you use, camera wise? All i have for when something interesting appears is a bloody phone!

By: PMN - 9th March 2010 at 22:15

Ha! Thanks! I don’t upload to A.Net much, I only have about 120 on there. JP is my main aviation site but I should try firing a few more in A.Nets direction!

Paul

P.S. The G&L’s Baby No.1 and it has to be said, she’s a beauty. I just have to learn to play it now! 🙂

By: PBY-5A - 9th March 2010 at 22:03

Thanks for the replies, i had a feeling it was to do with the bypass ratio, but i wasn’t sure exactly how, now i finally know! And Paul, some great snaps on your flickr – have you uploaded many to airliners.net? Got some nice basses too 🙂

By: EightSevenNorth - 9th March 2010 at 21:39

I’m sure someone more knowledgeable than me can elaborate further!

No need, a perfect explanation there.

The JT8D as used on the 731/732 is only about 3/5 the length of the entire engine nacelle.

By: PMN - 9th March 2010 at 20:58

They’re larger in diameter basically because the fan at the front is bigger. The JT8D on the 732 has a bypass ratio of roughly 1:1, meaning there’s an equal amount of core air and bypass air exiting the back of the engine whereas the CFM-56 on versions from the 733 onwards is more in the region of 6:1. To get that high bypass the fan has to be bigger, increasing the diameter of the engine. This created a bit of a problem with ground clearance on the 737, so certain components of the engine were mounted on the sides and the bottom of the engine pod flattened (it’s more noticeable on the 3/4/5oo than on the NG’s).

I’m sure someone more knowledgeable than me can elaborate further!

Paul

By: tenthije - 9th March 2010 at 20:55

I’m familiar with low and high bypass ration engines, my question was why are the actual shape of the engines so radically different?

The 737-100 pictured has a very long engine that takes up the whole diameter of the wing, and then some, while the 737-300 pictured below has a much shorter engine casing.

That is what i want to know.

That’s because of the high-bypass engines. The diameter of the fan of a high-bypass engine is a lot larger then that of a low-bypass engine.

For example, the diameter of the fan of a CFM56-7B18 engine is 1,55m. The diameter of a JT8D is 1,25m. Lengthwise the more modern CFM56 is a tad smaller. It looks a lot smaller probably because of the positioning of the thrust reverse on the older 737. Add a hushkit to that and the engine of a classic 737 looks longer still.

By: PBY-5A - 9th March 2010 at 20:40

I’m familiar with low and high bypass ration engines, my question was why are the actual shape of the engines so radically different?

The 737-100 pictured has a very long engine that takes up the whole diameter of the wing, and then some, while the 737-300 pictured below has a much shorter engine casing.

That is what i want to know.

By: Arabella-Cox - 9th March 2010 at 18:45

It is to suck in more debris from the runway. That is why they are sometimes called “Hoovers”. Just kidding. The higher bypass ratio (air going around the engine to air going through the engine) results in in significant fuel savings and noise reduction. Google “bypass ratio” or “turbofan engine” or similar keywords.

CHEERS

27vet.