October 5, 2015 at 2:37 pm

October 5, 2015 at 2:37 pm

I have been in touch with a former Bristol apprentice (1961) who was involved on the edges of the initial restoration of Bristol Bulldog K2227, now in the Hendon Museum as a static. As a drawing apprentice, he was tasked with redrafting a number of original drawings to support the restoration by other apprentices of this unique aircraft. His recollection is that the original project was coordinated by the supervisors of the apprentices, on the background of a more official resurgence of interest in steel construction for aerospace in the late 50’s and early 60’s. Notable explorations in steel construction at this time were the Blue Streak rockets using thin stainless steel pressure vessel construction to hold liquid fuel and the T188 high speed research jets using stainless steel skin constructed by Bristols.

The initial restoration, and subsequent rebuild by Bristol’s apprentices of the Bristol Bulldog after its early nose over overlapped the T188 development program, from 1953 – 64. The simple hypothesis is that scrap material from the T188 program was used in the Bulldog restoration in 1962. I wonder if there are any former apprentices from this time that could possibly support this contention with further evidence, or refute it with confirmation on what materials were actually used. One answer is to strip the linen from K2227 in Hendon and subject some parts of the original 1962 era airframe to non destructive handheld XRF analysis, but I doubt the rottweilers stripping the linen from my backside would allow this.

There are a number of circumstantial factors that support the hypothesis :

1. The original strip steel material the Bulldog was constructed of, a corrodible nickel chromium alloy with the splendid name of DTD54a, DTD99, DTD100 was obsolete by 1945, and no longer commercially available in the 1960’s.

2. The 35 year old engineers familiar with Bulldog strip steel construction techniques in 1935 would have been 60 years old in 1960, and still conceivably on staff at Bristols as senior engineers for the T188 project. The knowledge of materials used in 1935 and materials available in 1960, and the possibilities of applying them to various engineering outcomes would have been well within the compass of their experience and capabilities.

3. Stainless grades of material were used for naval variants of strip steel construction aircraft in the 1930’s, so the use of 1960’s stainless grades of material for the same purpose would have been unremarkable, and a valid pathway since the original nickel chromium alloy was not available. The 1930’s naval material was a ‘Staybrite’ 18-8 composition while the T188, according to Google, used an 18-8 composition with some titanium. I can imagine that the T188 material was very thin and high strength, and would lend itself to the very thin, high strength Bulldog airframe.

4. The fact that the restoration project was conjured by the supervisors of the apprentices implies, within the brew of institutional politics, a pitch to bean counters that emphasised no additional cost and making do with what was at hand. I find it more believable that the Bulldog was fabricated out of T188 scrap than good money was spent commissioning a coil of the original material for a requirement of only a few dozen feet of strip steel for what the company board might describe as an indulgence.

5. The fact that the restoration was undertaken by the Original Equipment Manufacturer, and material substitutions would have been supported by access to original calculus, with probably the same supervising personalities involved in the span between the last commercial use of the Bulldogs up to 1940 and the restoration of K2227 in 1962.

The requirement for replacement material was only really necessary once the restored Bulldog had nosed over in 1962, requiring the repair of tail fin and wing sections in 1962. As is more generally known the Bulldog was written off at Farnborough in 1964, until it was restored for static display between 1994 – 99, using remnants from other airframes and simpler carbon steels amenable to basic rollforming techniques to splice it together.

The purpose of driving this theory to completion, one way or another, is to most fully explore strip steel construction techniques and the inspiring vein of imaginative improvisation which characterised the rapid development of aircraft construction in the first half of the 20th century.

Ed

By: John Aeroclub - 7th January 2016 at 19:38

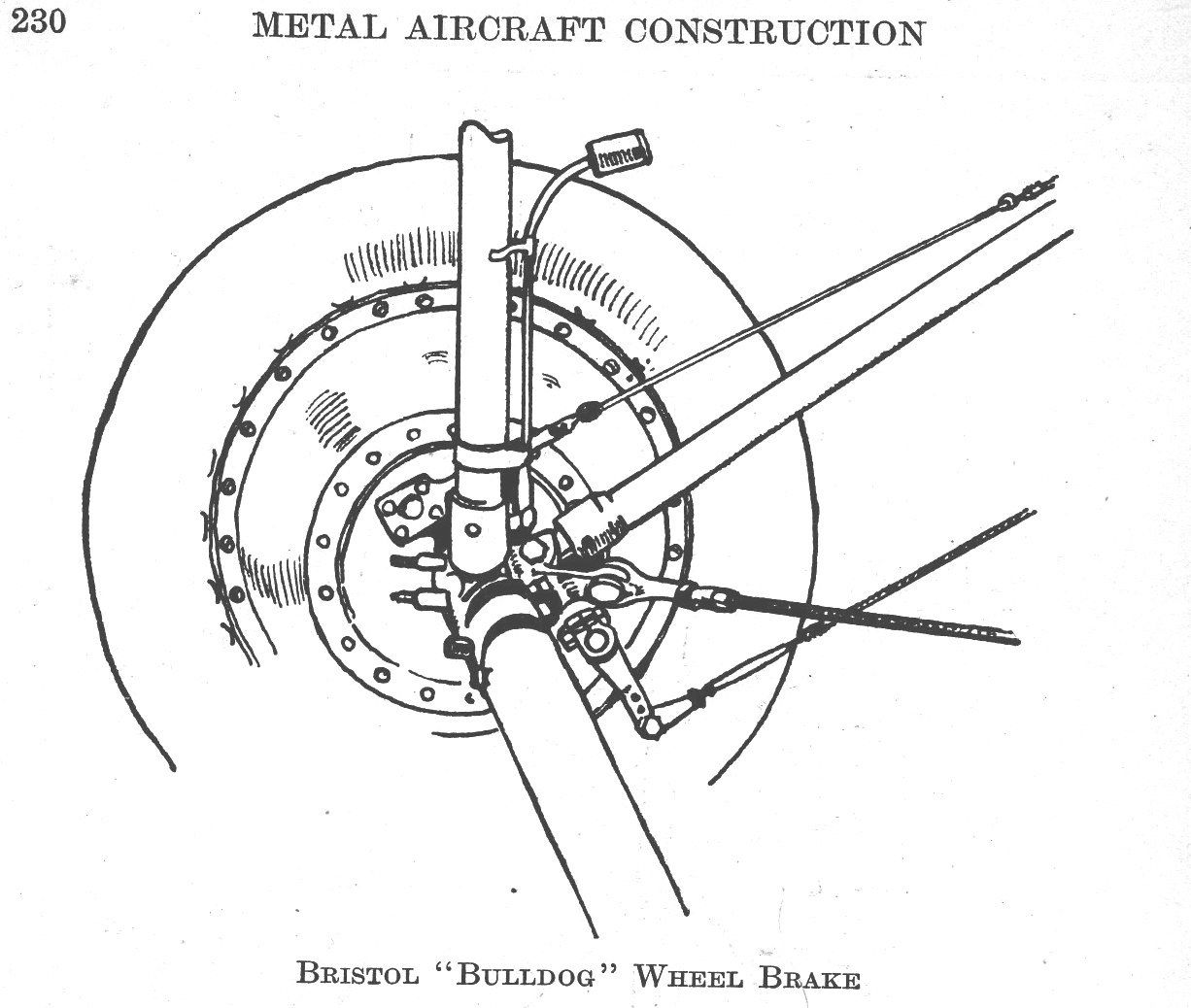

I’m sure that this will not help one iota but it may help folk down at my level to see the Bulldog brake. This illustration is from my 1934 copy of Metal Aircraft Construction (M Langley). I contains a huge number of such illustrations as well as material spec tables and D.T.D lists..

John

By: Bulldogbuilder - 7th January 2016 at 18:41

Ed2,

I will cheat on this subject, as I have in front of me a drawing showing the braking system as mechanical. I also have pictures (thanks Bret) showing an “arm” on the backside of the brake assembly. So far I have not found the callout for the Dunlop No. of the brake assay. at the wheel. The brake is an ‘after market’ item, and was stabilized (read- anti rotating) by “a” rod from the rear spar. Then some ‘erk’ pushed the aeroplane backwards (with brake set) and the discovery of the needed second anti rotating rod was established.

Chris B, I have that same vague thought. My thoughts at this time would be that the brakes are for approaching the fuel pumps.

Ed2: Do not eat (sugar) powdered donuts, as back snorting could result in the unwanted interest of the drug police.

Cheers,

Ed1

By: Chris B - 6th January 2016 at 14:28

I have a vague memory from reading a mag around the time the Bulldog nosed over (? RAF Flying Review) that it inadvertently taxied over a depression in the ground – possibly a drainage channel or depression caused by a buried cable, hence the nose over.

By: powerandpassion - 6th January 2016 at 03:47

how did Capt Audy nose over the Bulldog?

Not knowing the circumstances of the nose over I can only guess at the following :

1. The Bulldog was originally designed with no brakes, certainly Bulldog IIs supplied to Australia in 1930 had only spoke wheels with no brakes.

2. The CoG of the Bulldog, with a heavy Jupiter out front and ultra lightweight rear fuselage, would make it prone to tip over if brakes were fitted and applied excessively.

3. A recent trip to Shuttleworth elicited a comment from a pilot familiar with the Demon I, fitted with hydraulic brakes and Hind, fitted with pneumatic brakes, that Demon hydraulic braking was sluggish and Hind pneumatic braking ‘bitey’. So two similar aeroplanes with different braking systems create the option of riding into a hedge or nosing over.

Don’t hold me on this but I think Hind was 15 inch wheel and Demon 19 inch wheel but both use the same expandable ‘bicycle tube’ with friction pad mechanism, one expanded with hydraulic fluid and one with air, so they are a reasonable ‘test and control’ for considering fluid mechanics. This is Limey technology while Yankee technology of the day is the Bendix type brake shoe.

4. I do not know if Bulldog K2227 was fitted with hydraulic or pneumatic brakes. From photos, it was fitted with 19 inch Dunlop braked wheels in 1962, which could be either hydraulically or pneumatically driven.

5. My punt is that the Bulldog was fitted with pneumatic brakes which combining with a CofG closer to the engine than most types and a test pilot more used to trying to stop supersonic jets from coming off the end of short runways gave us a nose over.

Stearmans seem to nose over, from what I see on youtube. Hydraulic or pneumatic?

Maybe fit hydraulic brakes ? Don’t call me if you hit the fence !

Ed2

By: powerandpassion - 6th January 2016 at 03:30

I just laughed so hard that a bit of donut out came out of my nose.

Talking metallurgy, unless you are into the joy of crystal formation, can be mind numbing, so I try to spice it up ! Causing donut to pass through the nose of a fellow human being while talking about BAC.A 1021 & BS 970 301S21 I will consider as one of my most eminent achievements in this field, thank you !

By: Bulldogbuilder - 6th January 2016 at 01:54

Ed2,

You, Sir, are a force of your own! That being said, keep up the good work. No telling where and what will be divulged. I do , however, have a question-not to steal from this thread- but… how did Capt Audy nose over the Bulldog? (I have a vested interest in the answer)

Cheers,

Ed1

By: Spartabus - 5th January 2016 at 15:44

I was browsing this whilst taking my afternoon snack. I just laughed so hard that a bit of donut out came out of my nose. You, Sir, have won the internet today.

By: powerandpassion - 5th January 2016 at 12:47

If the T188 contained BAC.A.1021 then Bulldog K 2227 was repaired using bits of supersonic jet ! Below are engineering notes from the second rebuild of the Bulldog by Bristols in 1963, when parts of the original structure were damaged in the 1962 nose over :

[ATTACH=CONFIG]243036[/ATTACH]

This note deals with the replacement of a roll formed fuselage strut, originally made from DTD 99, 55- 60T nickel chromium alloy (the note specifies the same strut being originally made out of the stronger DTD 54a, 65 – 75 T nickel chromium alloy, as an alternate. New question – were later Bulldogs, with more powerful engines, given uprated, stronger fuselages, by replacing DTD 99 with DTD 54a? There is a precedent in Bristol’s original 1920’s drawings for the Bulldog specifying S40 spars, later uprated to DTD54a in the Bulldog II….)

Anyway the 1963 engineering allows BAC.A 1021 at 26 SWG to replace the original nickel chrome member at 28 SWG, a pretty close match. What was BAC.A 1021?

A 1957 Report by the Air Ministry on work conducted by Bristols on ” DTD 166 Type Austenitic Chromium Nickel sheet – a summary of Properties” describes BAC.A 1021 as a proprietory Bristols specification for, effectively, Staybrite with a touch of titanium. DTD 166 may be familiar to aficionados of Hawker Hart biplanes and Hurricanes as the stainless steel fish plates used to join the tube fuselages together. It is a ‘work hardening’ type of stainless steel, not for heat treatment. It seems a further twenty years of research and development, and the addition of titanium, allowed it to be weldable, as the report describes its chief characteristic is being amenable to puddle weld to FV 448, which the T188 was clad with. So BAC.A 1021, a lower cost material than FV 448, may have been part of the T188 structure, under the low creep (low expansion under the heat of friction from smashing through air at high speed) FV 448 skin.

The other aspect of the report deals with a new process called “Modulus Recovery Heat Treatment”, where this hitherto non heat treated material was subject to heat treatment at a very specific temperature range to significantly increase its strength. So BAC.A 1021 was a very clever material, described in the 1957 report as ‘high grade aircraft material’.

So certainly we have proof that ‘high grade aircraft material’, suitable for welding to the skin of the T188 was used in Bristol Bulldog K2227 in 1963.

Interestingly, BAC.A 1021, supplied by Firth Vickers, is described in the report as ‘basically Firth Vickers FDP’.

Climbing out of the Chesterfield* in front of the crackling fire* and reaching over to the oak* panelled bookshelf for my 1962 Firth Vickers “Rust, Acid and Heat Resisting Steels” sure enough confirms that the chemistry of BAC.A 1021 and FV FDP match. FV FDP is in the same section as Firth Vickers 301, Austenitic stainless, work hardening, basically Staybrite.

Ringing the bell*, I ask my man* to fetch my CAA AANs to refresh myself on the wing spar materials used in the restoration of Hawker Demon G-BTVE in the 1990’s, which show 301S21 as the material selected by Ron Dack, known to some as Yoda. I have to grab my Nachschlagerwerk Stahlschlussel from out of the hands of Brigit*, the 18* year exchange student from Germany, who is using it to set up a line of coke*, to confirm that BS 970 301S21 is the same as FV 301, which it is, basically Staybrite.

Understanding that the titanium in BAC.A 1021 was only there for weld stability, and that the roll formed sections in the Bristol Bulldog and Hawker Hart biplanes did not require welding, it appears to be entirely logical to use work hardening Staybrite for 1930’s roll formed strip steel structures, as long as you know what you’re doing. Most fascinating in the story of the Bulldog made out of T188 jet is the connecting thread between the work of the 1930’s builders of biplanes who became the 1960’s makers of steel based supersonic jets and on to the 1990’s restorers of old 1930’s biplanes. Who was Yoda’s Obi Wan Kenobi?

Certainly it would be good to continue the thread. Yoda is no longer with us, but I feel the Force. May the Force be with you.

*NB – Some aspects of the descriptions given above are not true.

By: powerandpassion - 8th December 2015 at 09:57

Thank you. Quite a remarkable document to put into storage – is there some way to verify that it exists and can be accessed ?

By: Wulfie - 5th December 2015 at 07:59

hi,

i think you are referring to a PhD thesis by Les Whitehouse, a BP engineer which was in the BP archives, which I found when I was writing my own Putnam history of the Company. I only photocopied some chunks of it for my own purposes. The weighty tome is I suppose with the archives which were donated to the RAF Museum and as far as I know are in store in Stafford

By: powerandpassion - 5th December 2015 at 02:10

Wulfie,

You included some extracts of what looks like a history of BP. Is it possible to have a complete copy? Very interesting reading!

By: powerandpassion - 1st December 2015 at 06:06

Wulfie, it’s arrived ! On the custom’s declaration it says “Fragment of crashed aircraft in biscuit tin”. What there is, instead of biscuit, is the Faberge egg of strip steel construction, real B&P spar, something I thought I would never see in my life, remarkable! Thank you. I will subject it to all sorts of metallurgical testing indignities and report back.

By: powerandpassion - 22nd November 2015 at 03:06

Thank you, very much looking forward to it.:eagerness:

By: Wulfie - 20th November 2015 at 08:05

The brochure arrived yesterday. The fragment of Overstrand spar and further information on Boulton & Paul steel techniques, are parcelled up before me, and will be sent today

By: powerandpassion - 20th November 2015 at 06:29

Wulfie,

Sidestrand brochure strapped to leg of pigeon winging its way over to you – you have PM

Wulfie, did the beautiful, rare, expensive, original brochure sent in trust for your Museum display arrive ? No PM reply from you!:apologetic:

By: powerandpassion - 5th November 2015 at 10:51

Fastest Bulldog

Here is the Bulldog-T188 in modernist magazine pose, that is before post modernism came into vogue and it became evil to manufacture these sorts of things in the UK, pictures of rampaging jets no longer suitable reading material for youth, who instead of reading about boldly injecting unburnt fuel into the stratosphere were forced to eat celery and read Catcher in the Rye, turning them into the miscreants of today scratching graffiti onto trains. As I was saying here it is :

[ATTACH=CONFIG]241748[/ATTACH]

A close up of test pilot Godfrey Auty, who nosed over the Bulldog in 1962, and might have unscrewed a few T188 panels and given them to the apprentices to fix up the damage.

[ATTACH=CONFIG]241749[/ATTACH]

By: powerandpassion - 5th November 2015 at 10:32

Wulfie,

Sidestrand brochure strapped to leg of pigeon winging its way over to you – you have PM

By: Wulfie - 26th October 2015 at 08:08

I have quite a lot of information about B & P’s pioneering metal aircraft technology. I will see if I can photo-copy it. I don’t know how to post photos on the Forum, but I could e-mail you pictures, if you pm your e-mail address. One of the spar pieces I swopped for a section of Wellington Geodetics. The other three (plus the new small piece) are on display in the Tettenhall Transport Heritage Centre. The only other bits of B & P steel structure I know of are the R.101 pieces which Shuttleworth hold, a R.101 piece which I think Fenland still have, a five long wing section in the Science Museum, which doesn’t have a provenance but might be Bluebird IV, and the P.10 wing and tailplane held by the Bridewell Museum in Norwich, but the latter are B & P’s first attempt at a metal airframe, dating from 1919, so are not typical. There used to be a display of all the sections B & P made in the Science Museum dating from 1927, but these parts were returned to the Boulton Paul Association who are in the process of dispersing their collection across the country, so I have no idea where these parts may be.

By: powerandpassion - 25th October 2015 at 23:00

Boulton & Paul did sell their technology to other companies, both Saro and Blackburn used their system. In fact B & P built the Bluebird IV wings and the London flying boat wings. They also received royalty payments covering some of their metal patents. Hawker paid them royalties, early on, for some of their spar patents.

I retract my statement that B&P ‘”did not sell their technology to other constructors”, I am wrong ! I do not know much about B&P as a company and their strip steel work, from leading the field in the late 20’s, seemed to become overshadowed by Hawkers with their Hart biplanes and Bristols with the Bulldog. Were the royalties paid by Hawkers in relation to the concept of the system of standard spar elements being combined into different sizes of spar ? Do you have any pictures or information on the Bluebird and London wings and the era of strip steel construction at B&P that you can share? Do you know of any other remnants of B&P strip steel construction anywhere ? Thank you, Ed

By: powerandpassion - 25th October 2015 at 22:54

The small piece, about 5 in. long, slightly bent, I cut off this ragged end for the new display, left the rusty remainder, about 7 in. of broken spar. You can have this in exchange for the Sidestrand brochure to go with our display.

Wulfie, happy to send the brochure for your Museum display, please PM your postal details. In the spar remnant, I am after enough material to sample the boom and flange, the ultra thin web in the middle and the large rivet that goes through the centre. Each sample does not have to be big, but if those elements can be salvaged from the 7 inch piece that will do. Can you post up some photos of the larger pieces of spar, this would be fascinating to see. No doubt the farmer would of had some nice roof beams – is there any history in relation to the aircraft they came from?