January 27, 2015 at 1:04 am

January 27, 2015 at 1:04 am

i find this quite amusing

A radar absorbing composite includes a (CNT)-infused fiber material disposed in at least a portion of a matrix material. The composite absorbs radar in a frequency range from about 0.10 Megahertz to about 60 Gigahertz. The CNT-infused fiber material forms a first layer that reduces radar reflectance and a second layer that dissipates the energy of the radar. A method of manufacturing this composite includes disposing a CNT-infused fiber material in a portion of a matrix material with a controlled orientation of the CNT-infused fiber material within the matrix material, and curing the matrix material. The composite can be formed into a panel which is adaptable as a structural component of a transport vessel or missile for use in stealth applications.

The barrier coating can also be less than 10 nm, including 1 nm, 2 nm, 3nm, 4 nm, 5 nm, 6 nm, 7 nm, 8 nm, 9 nm, 10 nm, and any value in between.

FIELD OF INVENTION

The present invention relates to generally to radar absorbing materials.BACKGROUND

Low observable, or stealth, technology is utilized on aircrafts, ships, submarines, and missiles, for example, to make them less visible or observable to radar, infrared, sonar and other detection methods. Various radar absorbing materials (RAMs), which absorb electromagnetic frequencies, such as in the radar range, have been developed for such low observable applications. However, the RAMs presently employed have some drawbacks. For example, many RAMs are not an integral part of the surface of a low observable structure. Instead, the RAMs are applied as coatings or paints over the surface of the low observable structure making them heavier, and prone to wear, chipping, and failure. An example of such a RAM includes iron ball paint, which contains tiny spheres coated with carbonyl iron or ferrite. Moreover, these coatings require bonding to the surface of the structure because they are not an integrated part of the structure or surface.Another example of a RAM is urethane foam impregnated with carbon. Such RAMs are used in very thick layers. Such RAMs are inherently non-structural in nature such that they add weight and volume to structures while providing no structural support. These types of foam RAMs are frequently cut into long pyramids. For low frequency damping, the distance from base to tip of the pyramid structure is often 24 inches, while high frequency panels can be as short as 3-4 inches.

Another RAM takes the form of doped polymer tiles bonded to the surface of the low observable structure. Such tiles which include neoprene doped with carbon black or iron particles, for example, are prone to separation, particularly in extreme operating environments such as extremely high or low temperatures, and/or high altitudes. Finally, numerous RAMs do not perform adequately in the long radar wavelength band, about 2 GHz.

It would be beneficial to develop alternative RAMs that address one or more of the aforementioned issues. The present invention satisfies this need and provides related advantages as well.

SUMMARY OF THE INVENTION

In some aspects, embodiments disclosed herein relate to a radar absorbing composite that includes a (CNT)-infused fiber material disposed in at least a portion of a matrix material. The composite is capable of absorbing radar in a frequency range from between about 0.10 Megahertz to about 60 Gigahertz. The CNT-infused fiber material forms a first layer that reduces radar reflectance and a second layer that dissipates the energy of the absorbed radar.

Original Assignee Lockheed Martin Corporation

http://www.google.com/patents/US20100271253#v=onepage&q&f=false

Lockheed Martin has revealed the F-35 Lightning II will be the first mass-produced aircraft to integrate structural nanocomposites in non-load bearing airframe components.

A thermoset epoxy reinforced by carbon nanotubes will replace carbon fibre as the material used to produce F-35 wingtip fairings beginning with low rate initial production (LRIP)-4 aircraft, said Travis Earles, a manager for corporate nanotechnology initiatives.

Meanwhile, the same carbon nanotube reinforced polymer (CNRP) material is being considered to replace about 100 components made with other composites or metals throughout the F-35’s airframe, he said.

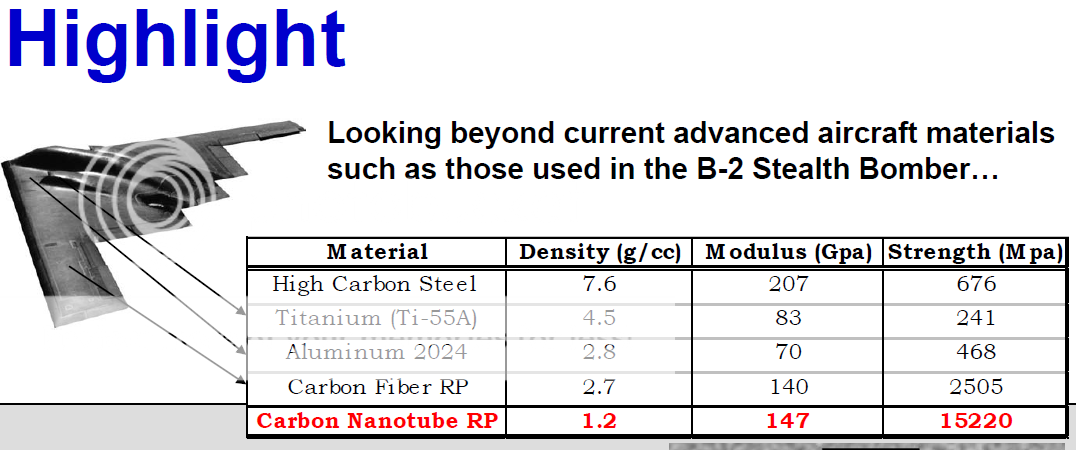

The shift to CNRP as an airframe material has been anticipated ever since carbon nanotubes were discovered in 1991. It is widely considered one of the strongest materials ever invented – several times stronger than carbon fibre reinforced plastic (CFRP), yet lighter by about 25-30%.

Lockheed Martin reveals F-35 to feature nanocomposite structures

http://www.flightglobal.com/news/articles/lockheed-martin-reveals-f-35-to-feature-nanocomposite-357223/