February 7, 2006 at 10:07 pm

February 7, 2006 at 10:07 pm

An older but recently revived thread asks “[what is] the most eagerly awaited warbird restoration?” and one of the answers is: a Mosquito! In that regard, our down-under restoration man Setter makes the observation re. the Kiwi Mossie that: “there isn’t a wing yet to speak of and this is arguably the biggest task of the project”.

Made me stop and think. Isn’t/wasn’t there a serious problem with Mosquito longevity o/a they’re made of plywood? Why would you spent thousands of hours/$ rebuilding something that will have a limited life-span? Perhaps a flying Mossie has to be a new build using different materials.

Or have I got the wrong impression?

By: Harald - 11th February 2006 at 05:58

To add to the above regarding PVA glue. Apparently they’re not generally suitable for guitar building as they have a tendency to creep over time. Not ideal on a wingspar, at a guess. Melv, comments?

I don’t know much about guitars, but I have been told by a cellist friend that the glue on a string instrument like a violin or cello is always weaker than the wood (think Stradivarius or Guarneri) so that if anything breaks, it is the glue joint, not the wood.

Harald

By: Dave Homewood - 11th February 2006 at 03:50

Thanks John. I had wondered what they were. I thought maybe the bottom one was a Miles product but it didn’t look right for one of their’s. Cheers. I hope the very old article was of interest.

By: J Boyle - 10th February 2006 at 14:44

To fill in some of the information show in the pages sent by Dave Homewood…

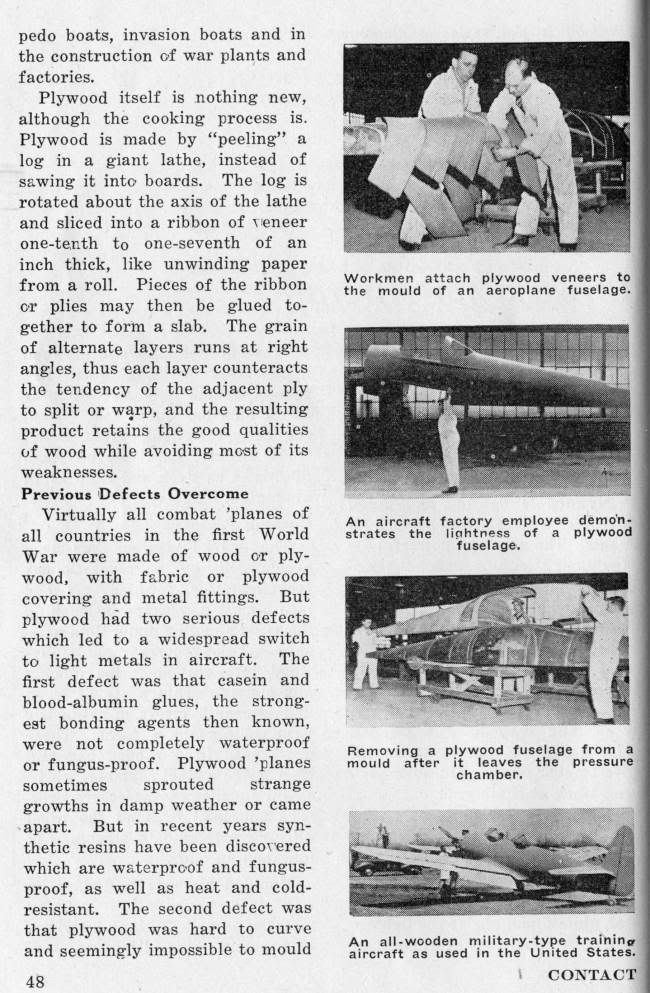

The AC being molded in the photos is an Ercoupe…thousands were made after the war in metal. This wood example must have been a test. I’ll check my other sources for details.

The wooden training plane shown is a Timm N2T Tutor made by the Timm Corp. It was built of plastic bonded plywood called Aeromold. Powered by a 220hp Continental, 262 were built for the US Navy.

By: alanl - 9th February 2006 at 21:08

Thanks everybody for their replies as to ‘how to’ build a wooden aircraft!

I will have to get the book from the museum shop.

I wonder how many other processes have been forgotten in the march of ‘progress’?!

Alan.

By: DazDaMan - 9th February 2006 at 11:36

The washout’s built-in as the foam cores are cut. The tip template is at a lower angle of incidence than the root so you get a steady decrease in incidence over the whole span.

I thought that was the case.

By: dhfan - 9th February 2006 at 11:30

Since I’ve only built R/C Spits with foam wings, I’ve never really had to build any washout into them.

The washout’s built-in as the foam cores are cut. The tip template is at a lower angle of incidence than the root so you get a steady decrease in incidence over the whole span.

By: Dave Homewood - 9th February 2006 at 11:25

I wonder if this May 1943 article from Contact, the Official Magazine of the RNZAF, is of any interest regarding the building of aircaft from plywood at that time?

By: DazDaMan - 9th February 2006 at 09:43

Since I’ve only built R/C Spits with foam wings, I’ve never really had to build any washout into them. However, on one plan that I had, the wings were built-up, and the outer ribs had tabs on the trailing edge in order to ensure the washout was added while you built it. The tabs were then cut off before skinning the wings in balsa.

By: Melvyn Hiscock - 9th February 2006 at 09:39

As stated elsewhere washout is basically a twist in the wing. The Rearwin has a little and this is achieved by shortening or lengthening the rear strut. On a Mosquito (and the Spitfire that has washout) it is done in the manufacture of the wing. This means very accurate and careful jigging to be able to duplicate it. If you have the means, as dH did and Glyn Powell is doing, then it can be achieved but the IWM wing would have to have a jig almost made around it and being a one-piece wing it takes a lot of space.

AJD have done an amazing job on the Yak 1 wing. That looked quite simple and almost ‘farmyard engineering’ until it was measured. That has taken longer than originally intended to rebuild partly down to the complexity of the spars.

By: dhfan - 9th February 2006 at 07:52

Washout, James and Ollie are both sort of right, although a little extreme. Not so much more leading edge down as less leading edge up, if you see what I mean. 🙂

Washin would be the opposite. I arrived at a mates’ house many years ago in time to see him building the wing for an R/C P-47. It was a few minutes before it sunk in that he’d got packing under the outboard leading edge instead of trailing edge. He’d misread the instructions. Would have given “interesting” flying characteristics.

The Mossie book I mentioned earlier is available through Abebooks at prices ranging from quite a lot of money for a paperback to eyewatering for a signed hardback.

By: mhuxt - 9th February 2006 at 01:44

Is there any book available that tells the story of how the Mosquito was built?

Nothing too tecnical though !

Cheers, Alan.

There’s an excellent little photocopied / reprinted article from “Aircraft Production” entitled “Construction of the Dh.98 Mosquito” available from the Mosquito Museum. Twenty-odd pages or so of the how-to.

Neilly, me old anorak, I now owe you 8,372 emails. Suffice to say the following: “Redundant, home, happy.” Details WILL follow!

Cheers,

Mark

PS – The B.35 pictured is in the Edmonton Aviation Museum, and is in the colours of 418 “City of Edmonton” Squadron, RCAF. Russ Bannock’s aircraft, to be exact. Tough enough making a living in Edmonton, let alone running an aircraft museum – give ’em some leeway.

PPS – The film referred to above is “The Mosquito”, 45 minutes of B&W goodness, also available from the Mosquito Museum. They take credit cards.

By: JDK - 9th February 2006 at 01:03

That second point brings me back to what I presume Alan was also thinking. If the Mosquito was this complex and exacting to build, how on earth were a whole lot of them built at speed in wartime? Was there a lot more coach-building or similar capability available? Or were they simply built to less exacting standards – as was the case with any number of aircraft and other weapons where longevity frankly was not an issue?

It’s an obvious answer really. If you have a production line, you can build a lot, relatively quickly; I think a chap called Ford figured that out. If you are building a few (essentially hand-building) it’s always going to take a lot longer.

Motor companies can knock out a lot of cars cheaply that you or I couldn’t build at home for ten times the cost because of the set-up cost, and jigs, tooling, training, etc etc…

Your first Mosquito wing is always going to be a challenge; by your 200th the wing fettler will know how much of a smidge to tweek the widget with his / her eyes closed. You, as a warbird builder, have to learn their job, do it once, then lean the next guys, do that one, and so on – making mistakes which need rectification as you go too…

The dispersed non-strategic builders (the furniture makers etc) were a factor, as you suggest, but a lot less important than the above points – as regards the lower standards idea, definitely not. They were built to a cost and a timetable, but not badly. Glynn’s doing a better job than DH in terms of quality of work, but DH weren’t building cheap junk either.

There was a film by DH which shows how Mosquitos were made. Very watchable, don’t know the name. Mosquito buff answer please?

HTH.

By: Smith - 9th February 2006 at 00:59

Thank you JDK – and yes John, I do remember that. At Auckland UNI the dunnies used to be underneath the student cafeteria. Some wit had scrawled on the inside of a cubicle “If you think the bottom’s dropping out of your world, dine at the cafe and let the world drop out of your bottom”

By: ollieholmes - 9th February 2006 at 00:56

What is washout and how does it work?

Do correct me if i am wrong here people;

Washout is where the trailing edge of the wing is slightly higher than the leading edge.

It is to prevent tip stalling as far as i understand.

I whant to know whats washin and what does it do? Does it induce a tip stall?

By: JDK - 9th February 2006 at 00:55

What is washout and how does it work?

Non technical answer as I understand it, toward the tip of the wing is twisted to have a more nose down angle of attack, with the result that at the stall, the tip will stall last, enabling lower speed control to be retained later; a straight wing (especially if tapered) will stall tip first resulting in a wing drop and stall/spin situation.

I think. 😉

By: Smith - 9th February 2006 at 00:48

Jargon question

What is washout and how does it work?

By: dhfan - 9th February 2006 at 00:31

Further to your comment on washout, I would guess there must be. The Mossie has a relatively benign stall for such a high performance aircraft with a highly tapered wing. The Handley Page slats originally fitted to the prototype were locked shut as being unnecessary. I find it hard to believe that would happen with the same incidence over the whole wing, although this could be a case of my little knowledge not being enough.

By: dhfan - 9th February 2006 at 00:20

There is nothing particularly complicated about a Mosquito – if you’re an aircraft manufacturing company with 20+ years experience of building wooden aircraft. 🙂

The techniques involved had been used by DH before, not least on the Albatross only 2 or 3 years earlier. Certainly they had to be revised or strengthened but it wasn’t like it is now, trying to re-learn long forgotten ideas.

Mosquito books, there are dozens. The one generally accepted to be the definitive article is called Mosquito, by C. Martin Sharp and Michael J. F Bowyer and was published in 1967 by Faber. It cost an arm and a leg at that time and myself and my dad had to wait until it came out in paperback and still bought it between us in 1971. It cost about 25 pints as a paperback!

The ISBN numbers are 0 571 04750 5 for the hardback and 0 571 09531 3 for the “paper covered”.

Thanks Melv. You posted while I was laboriously typing my reply. I started using aliphatic resins on model aircraft years ago and wouldn’t return to PVA.

By: Melvyn Hiscock - 9th February 2006 at 00:09

J

To add to the above regarding PVA glue. Apparently they’re not generally suitable for guitar building as they have a tendency to creep over time. Not ideal on a wingspar, at a guess. Melv, comments?

I have used PVA and not all PVA glues are the same. I have made guitars with Evo Stick Resin W and they are fine twenty years later. I now use Titebond, a yellow aliphatic resin glue. It is very, very good. I also read a lot of stuff on guitar-making websites about PVA glues creeping and 99% is without foundation. Some acoustic gutar makers claim that only hide glue will work properly but there is a lot of false science, and old wives tales, quoted.

However, you cannot use PVA on an aeroplane. There are glues now that are way better than World War Two. That is not the problem. The ex-IWM Mosquito has been looked at by a number of companies and the problem seems to be where the cut was made. Being close to the engine it is in the area with highest stress. 11:1 or 7:1 scarf joins are not that difficult but can get complicated if they have to be incorporated in a high-stress area. What appears to be a wing repair can almost become a complete spar replacement.

Even this can be more difficult than some people think. Is here any washout on the mosquito wing? That might mean having to jig the entire wing even for a small repair. Easy in wartime but not that simple now.

If making Mosquito wings was easy they would have been built years ago.

If it gets done I will be first to offer congratulations.

M

By: Smith - 8th February 2006 at 23:14

Is there any book available that tells the story of how the Mosquito was built?

Nothing too tecnical though !

Cheers, Alan.

I was thinking something like this when I briefly browsed last night and was mightily surprised by the quality of feedback to my question. Many thanks everyone. Lots of stuff I hadn’t appreciated.

So it seems …

1. Yes you have to be mad, but that might be a condition precedent for any warbird restoration :rolleyes:

2. No, a Mossie isn’t necessarily going to fall apart – but it’s a seriously complex thing to (re)build

That second point brings me back to what I presume Alan was also thinking. If the Mosquito was this complex and exacting to build, how on earth were a whole lot of them built at speed in wartime? Was there a lot more coachbuilding or similar capability available? Or were they simply built to less exacting standards – as was the case with any number of aircraft and other weapons where longevity frankly was not an issue?