October 16, 2017 at 7:15 am

October 16, 2017 at 7:15 am

It’s expensive to setup but finally an industrial job that allowed the equipment to be rented allowed me to sneak in some aeroplane bits for testing. In theory, dry ice blasting avoids blasting media contaminating a job with soda/sand/nutshells/plastic beads and scoring or pitting of soft metals such as aluminium, brass and magnesium. The traditional abrasive processes are also unsuitable where decals, painted features or fine surfaces such as die cast aluminium need to be preserved. It is so disappointing to get die cast aluminium returned from a blasting process with an anodized, smooth surface replaced with a matt, scored surface that can only be painted to disguise the damage. I also wanted to test various plastics, timber and basic paint removal without needing strippers, caustics, acids or solvents. Dry ice works through physical impact on paints made brittle by low temperature, as much as energy release from the conversion of solid CO2 to gaseous CO2 (sublimation, causing absorption of heat). I started on a venerable Victa 18 lawnmower which combined a good mix of plastics, metals, labels, paint, carbon build up and dirt. The idea was to clean the mower without damaging labels or softer materials, see what would happen.

The results were quite pleasing : hard carbon and baked grease buildup was removed from the fins of the aircooled motor. The injection molded high density polyethylene wheels with rubber tyres cleaned up without scoring. Die cast aluminium cleaned up without scoring. An adhesive, metallized, printed label cleaned up without fading or marking. Chrome plating was unaffected. Loose paint came off but well adhering paint stayed on. I did not want to strip the paint, but clean up the unit to allow cleaner dismantling. It took a minute to do and I was able to direct the dry ice into the carb and other nooks and crannies without fear of loading up the piece with blast media.

By: powerandpassion - 6th November 2017 at 04:09

Thanks for that. Quite an extraordinary result using an easy to find blasting media, most interesting.

By: ZRX61 - 3rd November 2017 at 23:04

Found the chalk blasting pics….

Click on the same pic at this link & it has details:

https://www.facebook.com/pg/ju88Gardermoen/photos/?ref=page_internal

By: powerandpassion - 3rd November 2017 at 06:24

Ghostbusters

Ghostbusters. I am there !

You could probably pay for it with graffiti removal services, and do your aeroplane parts after hours.

If it would remove wrinkles and fat, it could be paid off in two weeks.

By: powerandpassion - 3rd November 2017 at 06:21

CD, I would like to see those books, so when they cart you off make sure you put ‘for P&P on the forum’ on the end papers. I will donate a pint to your selected charity if your executor comes through !

Metal spraying is fabulous but hard to get a result on the nickel-chromium alloy steels subject to cyclical loading, like crankshaft journals. I am sure it is done, but maybe on automobile crankshafts subject to less loading or it is not talked about with regulators if done to spice up an aircraft crankshaft…In the case of resurfacing non load bearing conrod surfaces, sounds interesting….something keeps drawing me back to electro deposition, as a kind of slow, electron to electron dance of metal to metal passion, while spraying is a kind of crude, drunken, up against the trashcan quickie thing.

Chromium plating is an accepted repair scheme, I guess you are just replacing the chromium with the same material as the base, with Farlam-deposition*.

Laser sintering is making big inroads today, but not on load bearing surfaces such as crankshaft journals. I could see a pitted conrod machined down, all over, a few thou, then built up, all over, with laser sintering, then machined again, but it sounds like a lot of work. It’s putting heat into the work, while Farlaming* doesn’t.

A conrod, in extreme, is a piece of rubber stretching and collapsing with every revolution. You want the metal coating to stretch and collapse in the same way as the base material, which the Farlamocoat* would allow.

*Trade Mark

By: ZRX61 - 1st November 2017 at 20:30

The $500k price tag is for the big brute laser set up. What you can’t see is the rest of the gubbins which is about the size of a Hoochin start cart at the other end of the death-ray doodad the guy is holding in his hand. There are smaller/cheaper versions, including one that you can wear as a backpack*.

One advantage is that you can apparently set the machine to ignore which colors of paint you might want to preserve. I’ve seen one vid where it leaves the gray primer intact. You can also mess with the power setting to remove only one layer of paint per pass.

* You’d absolutely have to wear a GhostBusters uniform while using it 🙂

By: Creaking Door - 1st November 2017 at 20:10

Apparently ‘metal spraying’ is still very much alive-and-well in the large diesel engine world:

By: Creaking Door - 1st November 2017 at 19:59

I’ve got some excellent old engineering textbooks somewhere, from about 1950 I think, that go into exhaustive detail about how to repair what would, today (or even by 1980), be considered ‘impossible’ or rather uneconomic to repair. One of the examples was a large cast-iron crank-case that an engine had thrown a connecting-rod through the side; repaired by welding the bits back into the hole! Another example, I think, was for burned-out crankshaft journals. The process used here to ‘add’ metal before re-grinding the crankshaft was ‘metal spraying’ (which I’d never heard of until that point).

Maybe ‘metal spraying’ didn’t die-off some time in 1960 and could be used today to add metal to connecting-rods once the pitting has been ground out? Time for some googling.

By: powerandpassion - 1st November 2017 at 11:13

CD, it is Dagger, chunky style for 5000 RPM, big crank journals, pee wee piston. It was a ballsy design for the 30’s. It would have sounded quite different.

Yes the driving point of all explorations and enquiries is how to make 80 year old, rusty bits airworthy. If something is pitted, then this is unlikely, but I would still like to learn and explore. In fact the most simple and probably stupid thought has occured, stimulated by Farlams comment about using sacrificial iron anodes to restore corroded, iron based components.

Now if you took a 5% nickel-steel alloy conrod with pitting, and cleaned it up with, say, vapour blasting (mild, no peening), followed by dilute sulphuric acid pickling, followed by freshwater cleaning and you ended up with a conrod, that under the microscope, looked like the surface of the moon could you :

Use another, broken, 5% nickel steel conrod as a sacrificial anode, and via patient electro-deposition, fill the craters, sufficient to mitigate the propensity of stress corrosion cracking to develop from filled pits ?

Now this is an idea which is utterly sub economic from the perspective of a 1930’s parts manufacturer or operator with access to new spares. There would be no existing procedure that contemplates such a repair. But what if you dug up a Dagger from the ground today and over weeks and months restored otherwise unavailable conrods to service ? I have this gut feeling that electons are shed from pores in preference to uniform, bound surfaces.

By: powerandpassion - 1st November 2017 at 10:45

Laser wow

ZRX61, I had to look up vapour blasting, never heard of it, thank you.

As I understand it is glass bead or media in water. Good for keeping dust down, but still ‘matting’ die cast aluminium and introducing media into nooks and crannies. It looks like a great method for conrods though, thank you.

Now laser cleaning ! Wow ! I can only guess that light energy is exciting water containing iron oxide and causing it to blister off spectacularly. I would love to investigate this further. Thank you, very interesting. If it costs 500K to buy then this might be a little discouraging, but I can see the bones of a speciality business using things like laser and dry ice blasting to do ‘aerospace cleaning’, if somebody has the balls or fallopian tubes to put up the risk capital.

By: powerandpassion - 1st November 2017 at 10:36

DH82, Farlam and Alex, thanks for your comments. I try not to be too serious. Serious is for when you get pulled over by a four foot police woman with a truncheon.

Some years ago I tried to get to the bottom of molasses and as Alex indicates, any rust dissolving action is due to the mild sulphuric acid action, as well as a few organic ‘pot luck’ acids, acetic, butyric. In a commercial setting, such as ‘pickling’ before metal treatments like galvanising, dilute sulphuric acid is used to same affect, albeit quicker. So the same action results from mild sulphuric acid in water. If you have time, molasses is a lot safer, smells better and will probably biodegrade if tipped out into the back paddock. The requirement to wash down parts introduces ‘dirty water’ by a magnitude of ten into the whole equation, but this is a non issue where you accept 27 litre V12s burning holes into the space-time equation, making alien eyes water, as they should, for being so big, spooky and black. In fact everybody should keep some sulphated molasses around, to spray on and dissolve aliens, if they ever come. I hope some of these observations are useful. [ I did travel to Roswell, New Mexico, once, at night, alone, and it happened to be a lightning storm. So I pulled the car over, got out, looked at the sky and said “C’mon on.” No one came, except for a few deer. I guess the aliens were looking for intelligent life, and found nothing…]

By: HR339 - 28th October 2017 at 23:14

A technique for removing rust from steel that I have heard of, but not yet tried, is a mix of water and molasses.

Whatever chemical interactions that take place in the foul fermenting vat, eats the oxide without touching the steel.

Mix water with molasses in a 9:1 ratio and put your part in for as long as two weeks. Iron oxide is gone without touching the steel.

I realize this will not leave a polished finish, but you will have removed zero non corroded material. Cheap too!

We use this quite a bit with steel, because it is cheap and environmentally friendly. There are a few gotchas, like not using hooman food grade molasses because it is (a) expensive and (b) has the sulphates that do the reacting removed. It doesn’t strip paint which can be a bit of a pain, and it takes ages, but we have time.

By: ZRX61 - 27th October 2017 at 22:50

Laser on rust:

By: ZRX61 - 27th October 2017 at 22:38

Vapor blasting:

By: Flying_Pencil - 26th October 2017 at 21:16

Awesome test analysis!

Looks like a viable tool for restorations!

At least for static displays.

By: Creaking Door - 26th October 2017 at 21:01

What magical steps could remove the least material but still develop the smoothest possible finish today?

I wouldn’t worry about removing material; surely no amount of blasting with ‘soft’ media, glass beads for example, is going to remove sufficient material to encroach on the production tolerance of the rod? Not on the external surfaces anyway.

Is the intention to restore these rods to running condition? If that is the case I’d be more worried about leaving undetected deep corrosion pits than I would about slight overall erosion of the external surfaces. And the hidden internal surfaces would give me more concern than the visible external surfaces.

Once blasting has removed any corrosion, and revealed any deep pitting, the surface could be restored with wire-brushing and metal-polishing techniques but I’d still be concerned about missing (or covering-up) any concealed corrosion pitting damage.

You could test for cracks after abrasive-blasting but I think there have been some concerns recently that ‘shot-blasting’ can actually disguise cracks by ‘peening-over’ the crack edges and therefore making them much harder, or impossible, to detect.

By: Creaking Door - 26th October 2017 at 19:58

Is that really a Napier Dagger rod; it looks much later in its arrangement for something as early as a dagger?

I’m presuming the rod next to it is a Rolls-Royce Kestrel rod; see how angular it is with lots of nasty stress concentrating corners and angles. The early Merlin rods were the same but the later ones were far closer to the design of your ‘Dagger’ rod (not that it is a later Merlin rod).

It also looks a bit chunky; dagger pistons are tiny (even compared to Kestrel pistons).

By: DH82EH - 26th October 2017 at 14:50

P&P

I always really enjoy your threads.Your wit and writing style always make me smile.

I’d also be happy to stand you a pint, should we ever cross paths.

A technique for removing rust from steel that I have heard of, but not yet tried, is a mix of water and molasses.

Whatever chemical interactions that take place in the foul fermenting vat, eats the oxide without touching the steel.

Mix water with molasses in a 9:1 ratio and put your part in for as long as two weeks. Iron oxide is gone without touching the steel.

I realize this will not leave a polished finish, but you will have removed zero non corroded material. Cheap too!

Happy baking!

Andy

By: FarlamAirframes - 26th October 2017 at 10:24

P&P enjoyed the thread but quite a cost commitment.

For steel parts I like to use electrolysis in a dilute caustic bath with a sacrificial steel anode. Using a lab bench power supply and zapping it with a few amps for several hours.

No use for painted or aluminium parts as the caustic eats both.

By: powerandpassion - 26th October 2017 at 06:04

Trumper, thank you for your thank you, may you stub your toe on protruding metal in the grass and discover it to be a buried Spitfire, overloaded with gold bars…

Maxim, thank you for your insight – I do like plastic but the greenies are now going to chase you down for releasing ‘microbeads’ into the environment! I guess the whole advantage of dry ice is no blast media working its way into nooks and crannies, adding another ‘job to do’, to get it out.

Any subtle coriolis affects are dampened out by beer, down here, though you have to hold the glass to the left hand side of your face.

ZRX61, thank you for your insights on different media, and laser – most interesting.

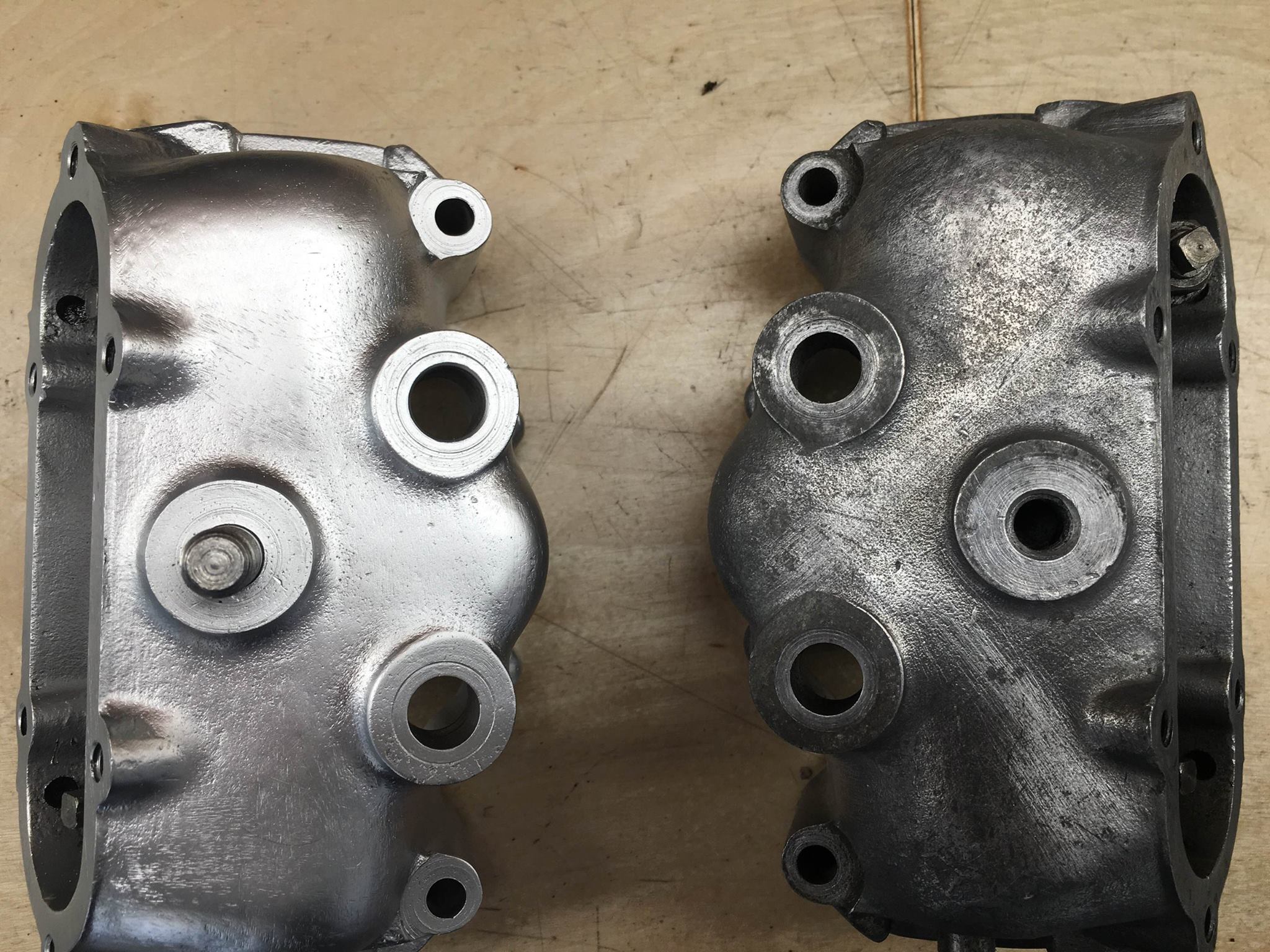

I would be interested on any ideas on treating the conrods in the pictures below – both over 80 years old, one looks like it was chromium plated ( Napier Dagger) and one ‘furry’ with surface rust. I assume, back then, that a polishing wheel was used on a machined part for the smoothest possible surface on a highly stressed part subject to cyclical fatigue cracking. What magical steps could remove the least material but still develop the smoothest possible finish today ?

By: ZRX61 - 25th October 2017 at 21:44

I find that many different processes need to be used for aircraft or car parts.

I use 2 completely different grades of plastic on both steel & aluminum. Nylon is soft & formica blasts paint/dirt into another dimension. Formica will also really ****** up soft aluminum.

Chalk works absolute wonders on electrical stuff

Aluminum (cast/forged) get blasted with different grades of glass bead & vapor blasting makes parts look better than new.

Soda leaves a nice finish on aluminum & brass.

Dry ice is ok for stripping sheet metal, but laser cleaning is the dogs danglies as it removes paint & corrosion in one pass. However: good news: costs about $4/hr to run the machine. Bad news: Machine costs almost $500k…