November 13, 2007 at 12:54 pm

November 13, 2007 at 12:54 pm

I have had the good fortune to obtain 2 complete volumes of the monthly Inter Avia magazines (1947 and 49) from a jumble sale for the princely sum of £2 each…. thats each volume not magazine, so I think I could call that a bargain!. It was a school neighbour who died and gave a load of “junk” to our schools Christmas Fund jumble. the loon was going to bin the lot until his wife said the school might want them to sell at that nights jumble! 😮 (I also obtained an 1899 OS map of Walsall for 50p and a 1933 The Motor Magazine map of England Wales and S Scotland in a mint wax canvas wallet for a quid)

Anyhow, I digress.

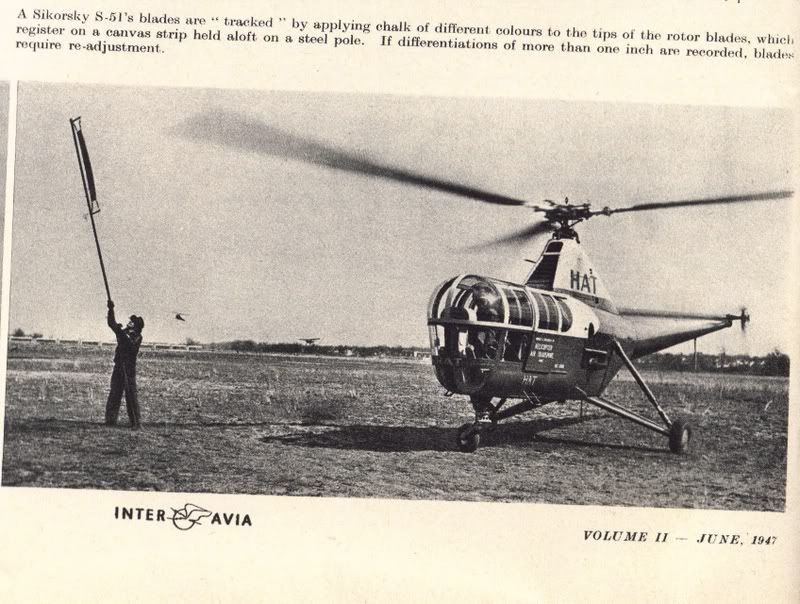

I found the following in the June ’47 edition on the precision adjustment techniques for Sikorsky choppers. 😮

Any of you know of similar life threatening, sorry, precision maintenance jobs?

By: Paul F - 14th November 2007 at 13:50

Thanks Chaps

Lindys Lad and bravoalpha – as I said when I asked the question, I was asking from a point of complete ignorance 😮 as you could tell. However you both answered my stupid quiestions in a constructive and helpful manner, cheers guys.

Paul F

By: hunterxf382 - 14th November 2007 at 08:47

There’s a video clip somewhere on YouTube showing a landing US Chinook having a rear wheel / leg propped up whilst in the hover. If I remember correctly it’s out in Iraq or Afghanistan, and the leg or wheel fell off. Groundcrew seen battling the downdraft to fix – incredible to watch!!

I’ve been blasted by a Chinook a few times whilst bringing them down onto the pan – breezy is an understatement, so hats off (not literally of course..lol) to these guys for sorting this Chinook.

By: Lindy's Lad - 13th November 2007 at 21:04

And I thought it was urban legend…. more like chinese whispers! 😮 😮

By: jackattack - 13th November 2007 at 20:26

I heard of a good one regarding an RAF Chinook:

One of the droop stops on the forward head sheared off, and the heli was kept running while a solution was found. The problem being that if the head was shut down, the unlocked blade would have chopped the poor wokka in half. The mechanics were tasked with getting as many mattresses from the block as they could and a giraffe (hydraulic steps) was placed in line with the advancing blades against the fuselage, and the matresses piled aginst the giraffe to protect the blade….

As the rotor head was shut down, the rotor brake was applied with force, stopping the head in a single revolution. As the unlocked blade lost its lift and went beyond the missing droop stop, it hit the mattressed giraffe and skipped over the fuselage saving the rest of the heli.

How true it is, who knows….:D

It was one of the the aft head droop stops. A tradesman found it lying on the pan. A Puma was sent to Boscombe Down as it was thought they had a video of an American aircraft with the same problem and what they did as a solution. Unfortunately it wasn’t so so they made a giraffe as you stated with plywood to stop the blade. Video was taken and slowed down to find which droop stop it was then the engines were stopped and the blades were stopped within 1.5 revolutions. I was there watching it all happen. All true except the front head bit.

By: Lindy's Lad - 13th November 2007 at 17:50

I heard of a good one regarding an RAF Chinook:

One of the droop stops on the forward head sheared off, and the heli was kept running while a solution was found. The problem being that if the head was shut down, the unlocked blade would have chopped the poor wokka in half. The mechanics were tasked with getting as many mattresses from the block as they could and a giraffe (hydraulic steps) was placed in line with the advancing blades against the fuselage, and the matresses piled aginst the giraffe to protect the blade….

As the rotor head was shut down, the rotor brake was applied with force, stopping the head in a single revolution. As the unlocked blade lost its lift and went beyond the missing droop stop, it hit the mattressed giraffe and skipped over the fuselage saving the rest of the heli.

How true it is, who knows….:D

By: bravoalpha - 13th November 2007 at 17:38

Blade tracking

I have to agree with Lindy’s lad on this one. I’ve carried out hundreds of tracking operations on Whirlwind and Wessex helicopters. The method was both safe and effective.

Assisting the droop stops with a wooden pole was another regular event and carried out from a small servicing platform on the side of the Whirlwind, however the operation wasn’t carried out with the rotor at full RPM, it was close to shut down when the stops were supposed to go in of their own accord (about 80rpm I think) so the aircraft had a fair old wobble to it with 2 blades sat nicely on their stops and the third playing silly b*****s. It had to be done though, the alternative was to risk the rogue blade chopping the tail off if the rotor brake wasn’t so good – and they really weren’t so good.

I’ve not changed a main leg on a hovering helicopter but once had to land a Whirlwind on some hastily piled flour bags from the catering flight when the nose leg dropped out.

Health and safety? When there’s all them rotating bits just by your head you act very safely indeed believe me.

By: Lindy's Lad - 13th November 2007 at 17:10

That method was viable with Whirlwind , Wessex and if absolutely required, sea king (static wicks would be damaged though and I’ve never heard of it done on this aircraft type). The idea is sound in principle, since the whole objective is to find a blade which flies high or low reletive to the others. The pole is in contact with the ground and the blades marked with different coloured chalk. By moving the banner into contact with the tips of the blade it is possible to see which blade is high or low due to the chalk deposits on the banner. Modern techniques have almost completely replaced this method, usually involving lasers, magnetic pick-ups or IR Cameras, or even strobe lighting.

As for the undercarriage affecting the readings – think of the helicopter as a gyroscope. It will take a huge amount of wind or undercarriage bounce to displace the rotor disk, and so the chalk readings will not be affected by any significant amount. The same can be said for play in the cyclic or collective – if there is play of any significant amount, then your helo is knackered and needs re-rigging. Also bare in mind, most helicopters have a scale on the barrels to adjust blade pitch, and so can be set with a fair degree of accuracy on the ground, given that the manufacturers will initially balance the blade and mark on it where the scale should read. (+1, -5, etc).

The chalk method is vague to an extent, or rather it is less accurate than modern methods. Which is better though – your rotor disk tearing itself apart, or getting LAC Moron / Mr. Moron the fitter to hold a flag against the disk?

Other life threatening jobs –

how about a main leg change on a Wessex? By the way, its in the hover and can’t land…. I know a bloke who did it on more than one occasion….

how about unsticking the droopstops on a Sea King .(For those who don’t know, droop stops prevent the blades from pivoting at the head when the rotorhead is rotating below a certain speed). The cure was to get a broom handle, and introduce the tip of it onto the droop stop while the head was being shut down….

By: mike currill - 13th November 2007 at 16:07

I seem to remember a TV programme about five years ago which tried to give the impression that it was a new idea. As far as I can remember the readings were taken directly in front of the aircraft exactly for the purpose of ruling out the difference between advancing and retreating blades. They actually claimed accuracy of <0.5″ IIRC

By: Paul F - 13th November 2007 at 15:27

Tell the youngsters of today that, and they won’t believe you…

(With apologies to Cleese, Chapman, Palin et al)

Maybe I’m being pedantic, and pardon my obvious ignorance of the quality of the engineering involved, but was that method really accurate to within an inch (thats 2.54cm for the youngsters amongst us 😉 ) – especially outdoors where a slight change in wind speed or direction, a slight movement in the undercarriage, or any “play” in the cyclic mechanism might momentarily affect the plane of the rotor disc?

I’d always assumed that a rotor disc might have more movement than that given the degree of droop and flexibility in the blades, and the fact that a gust of wind might add ten knots to one side of the disc and reduce airspeed by the same amount directly opposite? Were steps taken to allow for, and somehow cancel out, all the other possible variables first? Would the suspension travel be fixed by use of tie downs etc?

It all looks a bit “vague”, surely the position of the foot of the pole should be accurately fixed relative to the centre of the rotor disc? What happens if the guy holding the pole sneezes, or gets a lump of flying grit in his eye, and moves the pole towards the disc just that bit too quickly…..

I can imagine the same basic method working for a tracking a propellor, where rotation speed and tip speed might be much higher and where blades would be more rigid etc, though I’m not sure I’d feel any more safe standing close to the tips of a fast-spinning prop than I would holding the pole in the photo. I guess I’ve lost my sense of adventure – I blame modern ” ‘elf and safety” for wrapping me in cotton wool for too long.

….Oh, and I love the PPE (personal protective equipment) being worn by the engineer. If the pole falls into the rotordisc, and it all goes pear-shaped, it’s nice to know he’s wearing protective headgear………..

Those were the days…… Risk Assessment? Wot’s one of them then Guv’nor?

Paul F

By: WG-13 - 13th November 2007 at 13:56

A similar method was used for tracking Scout blades too, before the use of strobes and numbered tags attached to the tip-cap. The Scout jobby was mounted on a frame, and the arm holding the banner was rotated into the path of the blade tip.

If you heard a staccato ripping noise you were standing too close.

By: low'n'slow - 13th November 2007 at 13:43

I saw an old boy tracking the rotors on a Hughes 300 using just this method at Sywell last year!

Needless to say I gave them a very wide berth.

Mind you, I think he was wearing a hi-viz jacket so I guess he’d be all right :diablo: