February 3, 2017 at 7:28 pm

February 3, 2017 at 7:28 pm

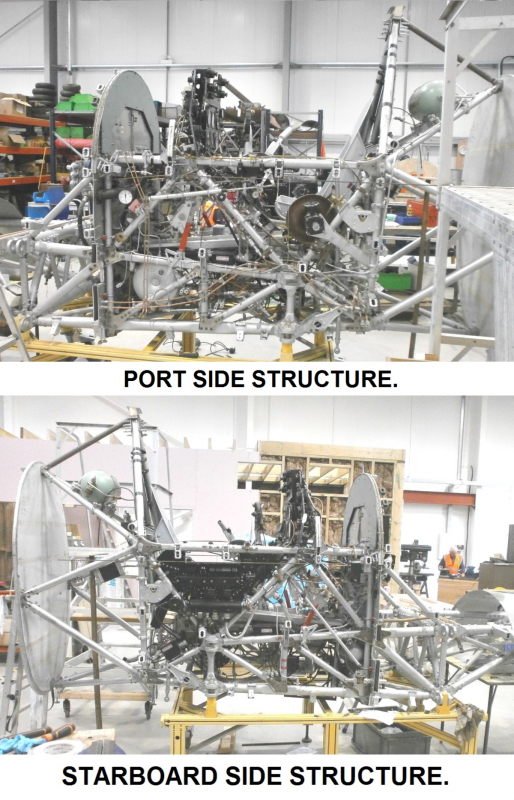

Having now pretty well completed the rectification/replacement of the cockpit frame structure at phase one; we are commencing fitment of electrical/hydraulic/pneumatic components; the completed flying controls module, and the pilot seat; followed by panelling and instrumentation.

[ATTACH=CONFIG]251123[/ATTACH]

The following components are still missing. If anyone has any of these that they are prepared to part with for suitable amounts of folding stuff, or knows where they might be available; any information would be most appreciated.

1x Newton Automatic Carbon Pile Voltage Regulator Type A.

1x General Services Junction Box. CZ. 22000/1.

1x General Services Junction Box. CZ. 22001/1.

1x General Services Junction Box. CZ. 22002/1.

1x General Services Junction Box. CZ. 12184/0.

1x Generator Suppressor. Type H.

1x Graviner Gravity Switch.

1x Dowty Hydraulic System Air Bottle Inflation Valve.

(Gauge: Budenburg Pressure (60lbs) 27Q/4863.

Valve Body: 27Q/3883 or 27Q/3884.)

By: windhover - 24th January 2021 at 10:42

Just to keep the interest going during the Covid Lockdown…

Ongoing assembly of the Crash Pylon, Installation of the Intermediate rear attack Armour plate, and general arrangement of Pneumatic Air Cylinder Layout.

(The Oval former at bottom right is the dummy locator for the ‘A’ frame.)

By: trumper - 23rd January 2021 at 10:46

Looks wonderful

By: No.2 A.A.C.U. - 23rd January 2021 at 10:27

That’s just wonderful thank you for the update

By: windhover - 23rd January 2021 at 08:24

For securing the Starboard panelling; the belly and lower radiator cowling panels, and the engine top cowling; the Amal fastener requirement is 69. The Museum management concept is for us to leave the port side open in order for visitors to view the internal structure and systems.

Meanwhile; here is the ongoing construction of the windscreen decking…

By: doughnut2020 - 15th January 2021 at 16:29

Good to see your work progressing. Interesting to hear about the Amal fixings (refer to another thread) how many of those fixing are required for the Typhoon ? I expect it is a time consuming job to machine each set of parts ? Not wishing to ‘arrange a marriage’ but would be interested to know how much information and parts you are sharing with other Typhoon / Tempest projects around the world and what a market there would be for a production run of such fixings. Are alternative ‘mass produced’ items available for the airworthy rebuild projects ?

I have no connection with any of the projects just an interest in seeing rare types rebuilt.

p.s. although it appear as I am a newbi my history on this Forum goes way back, formally CADman and before that DOUGHNUT

By: trumper - 3rd January 2021 at 15:23

Terrific , Thank you and keep well 🙂

By: windhover - 2nd January 2021 at 11:33

Due to Covid and assorted lockdowns, not too much info on our progress of late. However; this is basically as far as we’ve got. (Most of the plumbing is now installed and we are moving on to completing the windscreen decking.) Martin is producing replica Amal fasteners as these are literally unobtainable, and Tom’s tin bashers are starting on the rear monocoque formers (Supplied by Ian in Canada.) I’m sorting out the Fuel Tanks pressurisation system at present; (Suspended at the moment due to us being bunged into Tier 4 and consequently having the Museum locked down.)

Here is the old lady as she stands…

By: windhover - 20th October 2018 at 20:39

A couple more shots of the cockpit interior. First; the starboard side with the original starboard tread plate positioned to see

how much is actually missing prior to re-fabrication.

(The port one will have to be re-engineered as it was completely missing.)

[ATTACH=JSON]{“data-align”:”none”,”data-size”:”medium”,”data-attachmentid”:3838588}[/ATTACH]

And the port side…

[ATTACH=JSON]{“data-align”:”none”,”data-size”:”medium”,”data-attachmentid”:3838589}[/ATTACH]

By: baz62 - 20th October 2018 at 03:15

Rocketeer you mentioned the London to Christchurch Canberra as being at the scrapyard? I thought I saw the aircraft on display at the RAF Museum Hendon in 2001. Or was their another aircraft in the race?

By: windhover - 19th October 2018 at 16:44

Glad you approve of the plumbing Bruce.

All this lot has been formed by following (more or less) the original pipe run profiles, and bending by hand as the copper tubing has a nasty tendency to suddenly become oval in cross-section without the slightest warning if pipe bending tools are used.

By: windhover - 19th October 2018 at 12:13

Ian Slater’s project is still proceeding. He moved his Company and the project a while ago from the centre of Vancouver Island down to the south tip. His web site is dormant at the moment; but he regularly updates his Facebook page.

He has much to do… basically a full reconstruction; seeing as how Roger Marley’s replica… (the basis of JP843) was basically a mix of Typhoon and Tempest parts.

We are in frequent contact with him and various spare cockpit frame fittings we had in stock have been exchanged with him for original drawings and other relevant information.

By: CADman - 19th October 2018 at 09:40

Or indeed JP843 in Canada ? Hope that project is alive and well. Not seen any reports from there recently ?

By: Nachtjagd - 18th October 2018 at 15:10

Agree with the previous comments – truly fantastic work! Now I don’t want to start a bun fight on here but I wonder if there’s any interaction/coordination between you and the Typhoon (RB396) Restoration Project? I appreciate that this project is not being rebuilt to fly but it does seem that you’re streets ahead of the bigger project.

By: Bruce - 18th October 2018 at 14:20

Looks excellent – and as many aircraft used Tungum alloy which looked pretty similar, very few would know the difference. Also, Copper is much easier to form than Aluminium, and much more forgiving!

By: trumper - 18th October 2018 at 12:54

That is fantastic ,well done 🙂

By: Fouga23 - 18th October 2018 at 12:02

Looks great!

By: Sabrejet - 17th October 2018 at 21:46

Oh my word. Day trip coming up I think.

By: TEXANTOMCAT - 17th October 2018 at 21:35

Bloody Nora! More photos please! Well done chaps!

TT

By: windhover - 17th October 2018 at 20:27

Things moving on a pace now. We now have a production line set up for fabricating the monocoque formers by hand to original Hawker/Gloster drawings; and I am busy doing the plumbing.

It was decided on the grounds of cost to use commercial copper tubing (which is a tenth of the cost of the same diameter aluminium tubing and can be painted silver if required by High Command.) This will probably ruffle purist feathers but the project is only for static museum exhibition.

Here’s how it is going.

First the Port side…

[ATTACH=JSON]{“alt”:”Click image for larger version Name:tPort Plumbing.png Views:t1 Size:t764.1 KB ID:t3838370″,”data-align”:”none”,”data-attachmentid”:”3838370″,”data-size”:”custom”,”height”:”318″,”width”:”463″}[/ATTACH]

and the Starboard side…

[ATTACH=JSON]{“alt”:”Click image for larger version Name:tStarboard Plumbing.png Views:t2 Size:t463.0 KB ID:t3838372″,”data-align”:”none”,”data-attachmentid”:”3838372″,”data-size”:”custom”,”height”:”349″,”width”:”465″}[/ATTACH]

By: windhover - 13th February 2017 at 12:04

The Mk.1 seat fitted is ex-CARG stock which was donated to the project. It is an early Gloster Meteor Mk.1 Pilot seat, and conforms with regard to the mounting points; except, that the larger cast seat mounting inserts attached to the seat are of a smaller thread diameter than the two machined steel plugs/bushes that secure the seat to the adjuster handle on the starboard side; and the seat mounting bracket on the port side.

There are also slight variations in the side fitments (clips, brackets etc.)

The Lower Seat Frame Support Torsion Tube and seat adjuster assembly acquired from Graham Adlam; (Spitfire Spares), was marketed as being a Hurricane assembly, but is part number identical to that of a Typhoon. The only anomaly in the marriage of the seat to the support torsion tube and seat adjuster is the mounting inserts thread variation as mentioned above.

[ATTACH=CONFIG]251330[/ATTACH]

Up until the F8, all Meteors including T7s were non-bang seat and very much a case of “Sod this; time to go… I’ll have to step over the side.”