September 10, 2005 at 5:12 am

September 10, 2005 at 5:12 am

can anyone explain how a pumpjet propulsor works and is it too big to install on SSK ?

the newest lines of US and british SSNs have replaced the propeller with this.

is the water sucked in, the turbine is internal and the water jet pushed out of the back?

By: Neptune - 20th October 2005 at 18:04

Cool topic, must have been here before I entered this forum as I hadn’t seen it before.

One thing they all don’t mention. These “ducts” are basically constructed like an aircraft wing, take and aircraft wing, bend it downwards until you have a cilinder and there you have your duct. What is so special about this? Well, as you can see with aircraft, the air is bent down, pushing the wing up with a high pressure field below the wing, above the wing you have a low pressure field. As you can now see, the inside of the duct will have a much higher pressure inside, which allows the propellor to be much much much more efficient and turn on a much lower rate. So, instead of 87rpm, you will only need 60rpm (just an example) to have the same speed. This, together with the propellor diameter determin your water acceleration. Cavitation is created by the acceleration of water, this acceleration means a reduced pressure, and if you lower the pressure enough (below vapor pressure), water evaporates. When the water leaves the propellor, it slows down, and eventually the pressure rises again and the bubble collapses, creating noise.

There you have the other advantage of these propellors, you can go at much higher speeds without creating a huge amount of cavitation and at low speeds even prevent cavitation. Add to this that you have an engine running much slower and hence lower noiselevels and you have quite an idea why everyone is designing pumpjets.

The disadvantage is of course that it it’s not as easy as designing propellors because the parts have to fit quite well mechanically (otherwise it’s really screwed up).

On the other hand, what a scewed propellor does, is just stressing the blade tips of a propellor, making it more efficient once again, to lower the rpm. The bending “inward” of the wingtips is to reduce the diameter hence acceleration again. The blades can’t be built too “fat” though as the stresses would become too large then. But now everyone can build these as once you have seen one, you can give that image to some scientists and they will come up with the answer to what it does, just a matter of invention as is mostly the case. But sometimes the problem is deeper, like with a pumpjet, you can’t design one because you’ve seen it…

By: Skipper - 13th September 2005 at 09:38

Just before I left Rolls-Royce Marine last year I remember that the new Astute SSN propulsor is being manufactured from a Nickel Aluminium Bronze alloy with a composite shroud to reduce the corrosion problems previously seen on such applications.

Have a look at Page 11 here:

http://www.rolls-royce.com/marine/overview/news/indepth06.pdf

Regards

Skipper

By: Distiller - 13th September 2005 at 08:10

A pumpjet propulsor isn’t so much a ducted impeller, similar to that used on a lot of sports boats http://www.berkeleyjet.com/default.htm

The lower noise seems to be the result of the shrouding, not so much of higher efficiency.

By: sealion - 13th September 2005 at 03:21

I have the impression that one of the major problems of pumpjet is the clogging up by sand and mud while operating in shallow water or near shores. Pumpjets are also difficult to clean up and rust easily.

Even conventional propellors may have clogging problems while operating in dirty water. In fact, the Chinese Navy are kind of proud of themselves that they pretty much solved this problem. Remeber all those pictures in which the Chinese submarines are sailing in the extremely muddy inland river ? You better know what you are doing in that kind of environment !

By: Jonesy - 13th September 2005 at 00:57

Its sort of an inverse relationship but the closest I can think of would be a Tornado engine being optimised for the lower altitude flight regime – suffering performance loss at higher altitudes. Pumpjets simply dont perform as well at higher ambient water pressures.

By: Wanshan - 12th September 2005 at 18:22

Just a quick point to introduce into this is that pumpjets do have some quite significant drawbacks that come with the quieting advantage. Chief amongst these is the adverse impact that increasing depth has on the efficiency of a pumpjet system. Not sure how public this is but the prototype Spearfish HWT’s suffered significant performance degradation when fired at depth.

What would be the above water analogy for this ? Better jetengine performance at high altitude and worse at low altitude?

By: Jonesy - 12th September 2005 at 15:06

Just a quick point to introduce into this is that pumpjets do have some quite significant drawbacks that come with the quieting advantage. Chief amongst these is the adverse impact that increasing depth has on the efficiency of a pumpjet system. Not sure how public this is but the prototype Spearfish HWT’s suffered significant performance degradation when fired at depth.

By: snake65 - 12th September 2005 at 13:54

This is experimental pumpjet on 877EKM (Kilo) class. As this boat was the sole one, You can make an educated guess, that pumpjet for SSK was not a success :dev2:

By: WisePanda - 12th September 2005 at 13:18

a 9000t sub is a lil obese though to be going into shallow waters for spyin and keepin an eye on the unfaithful. they should have just purchased a couple of trafalgar boats off UK and used that logically.

but I guess once built they had to find a use for the Cold war relic.

By: Arabella-Cox - 12th September 2005 at 11:45

By the way, the Seawolf class is the first full-size submarines to be equipped with bow thrustors (2 on each side), which give it unprecedented low speed manueverability and docking capability. Bow thrustors have been used on tugboats and small submersibles, and now are widely used on large surface vessels also. Is anyone aware of other large submarines with bow thrustors ?

Interesting… nope, I wasn’t even aware the Seawolf had one!

By: sealion - 12th September 2005 at 02:18

the Seawolf is claimed “to be quieter at 20kts than a 688I tied at the pier” and the pumpjet probably contributes a lot to this.

Pumpjet or not, the 688I has to be running at full power without lubrication oil, while being tied at the pier, to surpass the noise level of Seawolf at 20 kts 😀

By the way, the Seawolf class is the first full-size submarines to be equipped with bow thrustors (2 on each side), which give it unprecedented low speed manueverability and docking capability. Bow thrustors have been used on tugboats and small submersibles, and now are widely used on large surface vessels also. Is anyone aware of other large submarines with bow thrustors ?

By: WisePanda - 11th September 2005 at 12:15

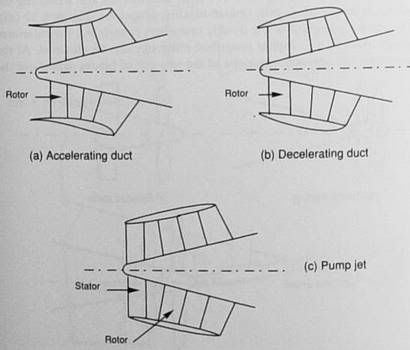

the drawing seems to suggest that, with the caveat of maybe multiple rotor & stator stages just like a turbine compressor. maybe the shroud helps to reduce the noise dispersion to a narrow cone behind the sub…rather than omnidirectional with a exposed single prop.

By: SOC - 11th September 2005 at 09:06

Isn’t this just basically a shrouded prop?

By: WisePanda - 11th September 2005 at 06:00

even the conventional props on SSKs seem to be closely guarded secrets. U-212 photos on dock always have the prop covered with a cloth.

http://www.naval-technology.com/projects/type_212/type_21217.html

so I’d think anyone who knows the internal layout of real in-service SSN kit will be keeping very quiet.

By: Arabella-Cox - 11th September 2005 at 03:25

Try searching google for “Hamilton jet”.

The jet boat propulsion method was invented by a Kiwi.

By: wd1 - 10th September 2005 at 16:14

i think i’ll take back what i said about efficiency … 😎

wanshan, the third link that you posted had some very interesting and enlightening illustrations, even though i don’t know french 😀 any idea then, if the pumpjets in the Trafalgars and Seawolfs use a rotor/stator combination, or just an “advanced design propeller” within the shroud?

By: Wanshan - 10th September 2005 at 13:38

Basically, the pumpjet works by the propeller sucking in water and spitting it out the back. Due to the spinning of the propeller, it makes the water twist and creates lots of bubbles, which are propelled out in the wake of the spinning blades. This creates lots of noise, so anti-swirl vanes are used to stop the swirling of the water and “kill” the bubbles. The pumpjet does not remove the wake. It works like a jet engine, water in becomes water out.

By: wd1 - 10th September 2005 at 13:21

my personal feel is that pumpjets are less efficient than conventional propellers. SSNs can afford to have the extra power output to maintain 30+kt speed despite the loss of efficiency (go have a look at the reactor output difference between a 688 and Seawolf to get roughly the same max speed).

but for an SSK every watt of battery power is precious, and cannot afford to be wasted with a pumpjet. in any case, SSKs are quieter than nuc boats, and do not (cannot) reach speeds greater than 20kts where cavitation and noise become a problem. they are quiet and not fast enough to require a pumpjet.

the pumpjet seems to make a lot of difference though. the Seawolf is claimed “to be quieter at 20kts than a 688I tied at the pier” and the pumpjet probably contributes a lot to this.

i’m not 100% sure about anything though. my only evidence is Tom Clancy crap (recently re-read Red October and Red Storm Rising), 688I and Seawolf spec sheets and my own grey matter. better informed contributions would be nice.

cheers!

By: Phil Foster - 10th September 2005 at 10:53

can anyone explain how a pumpjet propulsor works and is it too big to install on SSK ?

the newest lines of US and british SSNs have replaced the propeller with this.

is the water sucked in, the turbine is internal and the water jet pushed out of the back?

Royal Navy subs have been using this tech since the mid 80s mate though I don’t claim to know how it works.

Phil 🙂