August 19, 2004 at 1:01 pm

August 19, 2004 at 1:01 pm

Here’s a question. On this interesting website here recommended earlier on the forum, there’s an intreaguing mix of facts. One I’ve never heard of before is this:

“GOOD IDEA? An attempt by the Americans to cause a volcano to re-erupt ended in failure. In 1942, the Tavorvur volcano on Matupi Island, Rabaul, erupted and caused great concern for the Japanese occupation troops. To cause greater concern, the Americans purchased from the British Government two ‘earthquake’ bombs of the type invented by Barnes Wallis for the Ruhr Dams raid. The two bombs, together with a number of 2000 pounders, were dropped on the gaping mouth of the still smoking volcano. Both bombs missed the target and buried themselves in the sand near the end of the runway on the nearby Lukunai airstrip. In 1970, the two bombs were discovered unexploded. The Australian Navy was informed and the bombs were detonated.”

The questions I’ve got are as follows:

Is this true?

Which bombs were used? Tallboy or Grand Slam?

Given that the Lancaster was (as far as I know) the only wartime bomber configured to use these bombs, what was used to drop them?

Anyone?

By: irmurray - 16th August 2007 at 10:44

Hi Phil,

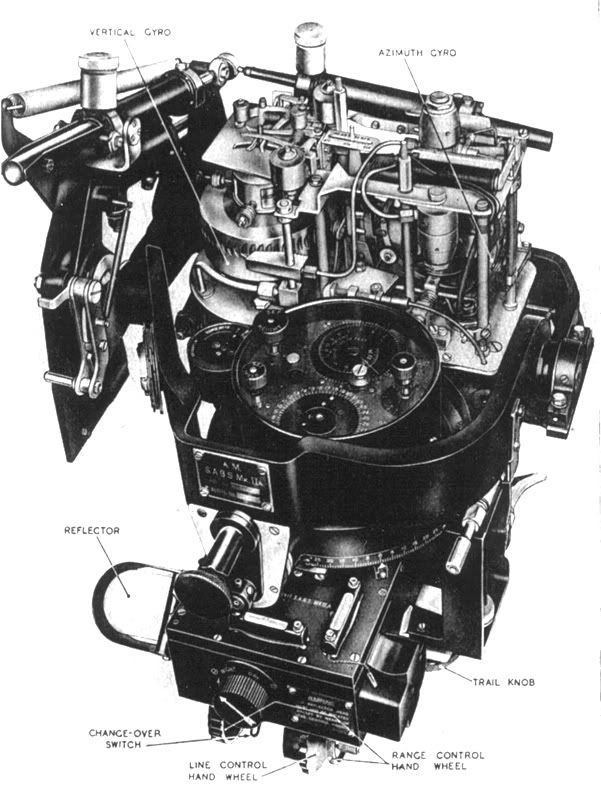

This site has been updated since I last saw it – it didn’t have pix before. Seems to be the only SABS pic on the web!

Thanks for the link/photo – much appreciated.

Iain.

By: Bruggen 130 - 15th August 2007 at 18:56

Super Phil, thanks – first time I’ve seen it! Is this the sighting head and computer in one unit?

Could I be greedy and ask if you have any more?

Thanks,

Iain.

Hi Iain.

I just put SABS Bombsight in to GOOGLE and this came up.

Regards Phil.

By: irmurray - 15th August 2007 at 17:08

Super Phil, thanks – first time I’ve seen it! Is this the sighting head and computer in one unit?

Could I be greedy and ask if you have any more?

Thanks,

Iain.

By: Bruggen 130 - 15th August 2007 at 17:05

Hi all,

I’m just back from holiday, and want to catch up on a few items in this thread …

Sorry to hear of the death of Henry Black – his documents are the best source of information I’ve seen on RAF bombsights.

SABS was a derivative of the Mk XIV / T-1 (it’s not the same), but there seem to be no photos or diagrams of the SABS, nor have any examples survived. It was supposed to be more accurate than the Mk XIV, but needed a longer run up to the target; it also dropped the bomb itself.

Hi

I thought this thread had long gone, this is a picture of SABS, nice bit of kit

sayings it’s about 63 years old, Still don’t think the Americans had any say how B. Wallis’s Weapons were developed.:D

regards Phil.

By: irmurray - 15th August 2007 at 16:34

Barnes Wallis and the Americans

Hi all,

I’m just back from holiday, and want to catch up on a few items in this thread …

Sorry to hear of the death of Henry Black – his documents are the best source of information I’ve seen on RAF bombsights.

SABS was a derivative of the Mk XIV / T-1 (it’s not the same), but there seem to be no photos or diagrams of the SABS, nor have any examples survived. It was supposed to be more accurate than the Mk XIV, but needed a longer run up to the target; it also dropped the bomb itself. The Mk XIV and T-1 were mechanically identical, T-1 was just the American manufacturing designation for the British Mk XIV design. You can tell the difference between Mk XIV and T-1 systems by sight, but the computer and sighting heads were interchangeable.

As far as I am aware from research in the Wallis archives, the Americans had no feedback into the design of the Upkeep / Highball / Tallboy bombs – though they may have been given copies of reports.

In late 1944, a B-26 Invader flew to Brooklands to be fitted with a Highball carrier. Although known as “Speedee” in the US, the bomb and carrier were identical to Highball (there were other code names for the same bomb in other aircraft too). Around 24 trials were made near Eglin AFB in Florida before the B-26 was destroyed by the bomb hitting the tail, and the Americans had no more interest in the weapon.

Tallboy and Grand Slam casings were manufactured in the USA, for shipping to Britain for filling. The UK casings were turned smooth on the outside, the US casings were left rough, and this caused some problems with fittings; I think some were sent for turning in the UK.

The offset tail fins idea can be traced back to arrows, and the application to bombs is obvious. Despite this, Tallboy was originally designed with straight fins, and after the need to offset them was discovered, Shorts (who made the tails) started sending them with the bolts loose so they could be offset in the field, although they were later asked to offset them at the factory to save time.

I have not seen any evidence that Upkeep was ever examined for production in the US, although it is possible. The original drawings have never been located, and it is the German drawings which are most often seen in print. The Germans got the idea for Kurt from the recovered Upkeep, they did not think up the idea independently.

Highball was not used for its main purpose (attacking the Tirpitz) for three main reasons – the X-craft were deemed as having a better chance of success so got to “go first”, the range to Kaa Fjord was a problem for the Mosquitoes (would have had to go via Russia), and the position of the ship in the fjord meant that a broadside attack would have been difficult.

I hope these comments are useful.

Regards,

Iain.

By: alertken - 7th August 2007 at 20:04

B.130 what a find! it took me to www.twinbeech.com/norden_bombsight.htm. I don’t think chaza87 is trying to own “our” work. His teamwork point is correct.

Tizard’s Sept.,1940 Mission gave goodies to a neutral, whose Lend/Lease came on stream March,1941; from 11 Dec.,1941 with common enemies we pooled spark plugs, fuel, bangers and mash, Ansons, whatever it took. Stalingrad/elAlamein2 secured UK’s oil, and Torch brought Forces Adm. King and Gen. MacArthur yelped for in the Pacific. So for 2 years we swapped Intellectual Property without legalising about royalties or kudos. UK resented exclusion from the Norden secret; little instrument-makers Ferranti and Elliott wondered how they would sell in Peace when our cavity magnetron was absorbed by vast-volume Raytheon; DH/RR were not wholly happy to share our turbines with big spinners Allis-Chalmers/GE. But there was a War on. UK brain+US brawn=the winning team.

From late-44, Victory evident, US brought back the $ sign and gave us grief, from civil air routes, to de-colonisation, to £-convertibility and their notion of Open Door. US’ 1946 UK Reconstruction Loan settled L/L, net of Reverse inc.Tizard: both of us buried our claims. From this period lurks such “theft” as of M.52 flying tail for X-1. By late-1947 Stalin concentrated US minds; Two-Way Street + Mutual Security $ have aided most everything we both have done ever since. Very hard for UK GW industry to claim a single solo-invention, hard for US to claim a single non-Space aero-innovation not influenced by UK Establishments. US’ industrial strength derives from Chevrolet churning out their horrible autos under the discipline of Production Engineering. Austin, say, never grasped this, but Japan Inc. did. If UK industry has declined, and if that was avoidable, it was not US’ fault.

By: Bruggen 130 - 7th August 2007 at 17:42

Seems to me that the T1 sight was a british invention to.

The T1 BOMBSIGHT STORY

Copyright :Henry R. Black, 2001

VERSION 26/07/2001

——————————————————————————–

I am indebted to Henry for allowing me to publish his article on World War Two T1 Bombsights

Note: I am sadden to advise the Mr. Black has passed away. His articles are left in tribute to his historical research.

——————————————————————————–

The story begins on the 22nd December 1939 at a wartime conference to discuss bombsight policy. A request was made by Air Chief Marshal Sir Edgar Ludlow-Hewitt, Air Officer Commanding Bomber Command for a new bombsight. He stated that the existing bombsights in service or about to enter service, did not meet the requirements of his Command. He wanted a bombsight that did not require such a long run up to the target and gave his pilots an opportunity to engage in evasive action on the bombing run.

His remark may have been prompted by the fact that four days earlier, Wellingtons of his command took part in a disastrous raid upon shipping off Wilhemshaven in which twelve of the twenty two Bomber Command aircraft were shot down. This defeat was to have major consequences for the conduct of WW2 as a whole. It marked the time when night operations became the major policy of the RAF Bomber Command, the point when radar was first used to detect raiding RAF bombers attacking main land Germany and the birth of the Mk XlV bombsight.

Although later correspondence records the fact that the AOC did make the request during this meeting, the detailed minutes fail to record his request although the volunteering of Prof. Blackett to design a sight to meet his needs was noted. Other documents of the time refer to this request by Sir Edgar Hewitt and so the need for the highest security may have lead for its omission from the minutes.

Through the influence of others present at the meeting he quickly obtained laboratory and engineering facilities at Royal Aircraft Establishment, Farnborough where he could design and initially develop the new bombsight which he based upon the principles of the existing CSBS Mk lX bombsight.

Professor Blackett was an eminent physicist of the time and in his capacity as a scientific advisor to the Air Ministry was present at the meeting. He had volunteered to design a bombsight that would meet the requirements of A O C Bomber Command. Thus was born the Blackett Bombsight. From that day forward, the proposed bombsight had an enthusiastic reception from the RAF and Air Ministry officials before even the first prototype was built.

His new bombsight proved to be the significant improvement that RAF Bomber Command required. The proposal met in full the requirements of the A.O.C Bomber Command.

It was first known as the Blackett sight and later as the MkXlV. It is interesting to note that it was first described as a medium altitude stabilised bombsight to be used within the 5,000 to 10,000 feet range. Later, the maximum altitude for which the sight was designed was 20,000 ft and later still increased to 25,000 ft. The first prototype known as the Mk Xll, consisted of the sighting head only with a second member of the crew feeding data into the sight. This was declared undesirable and resulted in a computer cabinet being designed and built which allowed the sight to be operated by the bomb aimer only. This was designated the MkXlV.

When the concept of the MkXlV had been proved, Prof Blackett left the project team for other important work in Coastal Command. Dr H.J.J. Braddick took his place and was later nominated by Blackett as the co-inventor of the sight.

At an early stage in its trials at the Aeroplane and Armament Establishment, Boscombe Down; it became recognised as the first bombsight whether British, German or American which offered reasonable accuracy in conjunction with a wide degree of tactical freedom. The tachometric bombsights such as the ABS Mk2, the later SABS and the American Norden with their longer run-ups were preferably used at heights above 21,000 ft to reduce the risk from anti aircraft fire.., This height that time was above the maximum service ceilings of the new four engine bombers, the Halifax, Stirlings and Manchesters.

The searchlight and gunnery defences surrounding a vital German target were often sited to take advantage of the short period when the attacking bomber had to fly straight and level to use in order to use its sight to accurately bomb the target. The shorter the run up to the target, the less opportunity it gave the anti aircraft guns and searchlights to aim at the bomber.

The new bombsight was required to be manufactured in quantity to equip the new heavy and medium bombers in production for Bomber Command. It was unique in that it could be built using relatively lower grade labour than either the Norden or the British Automatic bombsights. Both these bombsights required a higher proportion of input from high grade instrument makers in their assembly and led to considerable delays in the production of the Norden. The redesign of the Norden for mass production resulted in the introduction of significant errors which eventually affected the performance of the sight in USAAF service.

The Mk XlV has another little known advantage over its predecessor the ABS Mk ll, in that its bulk was smaller and was less of an impediment to the view through the clear bombing panel by the prone bomb aimer. A clear view through this panel was also important as it was used for map reading. This problem was so serious that consideration was given to providing with each bomber an alternative nose section with the front turret omitted giving space for a larger bombing panel.

With the prototypes of the bombsight operating satisfactorily, the enthusiasm continued for its future use in Bomber Command. This contrasted with the reception of its predecessor, the Automatic Bombsight that was received with little optimism for its eventual success.

At an early stage in its development, steps had to be taken to provide large quantities of the sights to meet the expansion of Bomber Command. The decision was made therefore to sub-contract production of the MkXlV to the USA, which would be additional to the output of British companies and also gain access to a much larger pool of labour.

Sperry Gyroscope Company of USA were approached by the British Purchasing Commission in Washington. This company already had many years experience in manufacturing bombsights which now included the S-1 tachometric bombsight then in production for the USAAF. This bombsight was designed to supplement the production of the Norden, which at that time was in chronic short supply for aircraft of the US Navy and United States Army Air Force and the subject of much controversy between those services.

Mr Vose of Sperry Gyroscopes of America expressed considerable interest in the MkXlV sight. He claimed that his company would be able to redesign the sight for mass production and in so doing, enhance its performance. He stated that at that time his company had development staff immediately available to undertake this work now that their Sperry-0-1 had largely completed development. He requested a set of drawings to be made available to his company with a sample bombsight being made available as soon as possible.

Before these drawings could be handed over the question of the patents involved had to be considered. Professor Blackett became involved once more with Dr Braddick. Dr Braddick of whom little is now known, had also played a leading part in the development of the SABS MllA and also the cancelled SABS Mklll. This former sight was in final stages of development around about the same time. Although manufactured in small quantities, (less than 1,000) it was used very successfully by 617 Squadron in its precision bombing. It was a further development of the generally unpopular Automatic Bombsight.

Mr Vose of Sperry, in making his case for the manufacture under license of the MkXlV optimistically implied that the USAAF would be interested in acquiring the bombsight for use on some of its types of bombers. Later an old Hudson was indeed equipped with a Mk XlV/T1 but the USAAF rejected it because of the requirement to set manually, a wind speed and direction and for lack of connection to the aircraft through the automatic pilot. These requirements were a feature of the Norden and Sperry bombsights.

The decision was made to subcontract the manufacture the Mk XlV to Sperrys where the American version would be known as the T1 bombsight.

When the initial development work had been completed by Sperrys they in turn subcontracted the work to A.C Spark Plug Company at their Flint plant in Michigan. This company was a division of General Motors.

This decision was probably due to the pressure on their Sperry USA factories in producing a large number of vital products for the American expansion of their own armed services.

Throughout the contract, Sperry production engineers supervised the production at the A.C Spark Plug plant. Some components such as the gyros were supplied ready to install by Sperrys

The section of industrial history which deals with the development and production of equipment for the armed services of any nation is very rarely recorded in any detail; company archives rarely survive for more than a few years and are often not available to the historian. The A.C. Sparkplug Company of Flint, Michigan was no exception to this rule and the author has been very fortunate in being contacted by Mr George A. Krepps in the USA who was an executive at the plant in WW2 throughout the period of the contract. His job was to supervise the quality control functions relative to subcontracted incoming sub-assemblies, final sight assembly and final test. His detailed recollections provide the basis for this article.

The plant provided at that time a number of products to the aircraft manufacturers and government defence departments such as sub- assemblies for the Sperry S-1 Tachometric bombsight. They were also building gun sights for fighter and bomber aircraft that were based upon British designs subcontracted to the Americans. There were also, of course, millions of spark plugs produced for use in both civilian and military internal combustion engines.

The RAF Air Staff in agreeing to these arrangements hoped that the American bombers produced in the USA would arrive in Britain with the MkXlV/T1 already in installed in their bombers.

Work on preparing the bombsight for mass production started in May 1942 with the first T1 being ready for test in November that year.

Initially, Sperry provided three production engineers to work with A.C. Spark Plug engineers in the reworking of the drawings so as to break the bombsight and sighting head mechanisms into sub-assemblies. They suggested improved production methods and provided the criteria to be used. Sperry took steps to ensure that test procedures and equipment met Sperry standards by the training of staff and supervisors.

Changes were made in the overall design of the computer cabinet to reduce the number of manufacturing operations required. The tubular frame which surrounded the computer cabinet was modified to reduce the amount of welding necessary.. All threads used on components were changed to American standard threads. Die castings were extensively used where ever possible in the sub-assemblies. Sintered oilite sleeve bearings replaced ball bearings. The higher standard machine and cutting tools available to the Americans further improved the output.

When it appeared to Sperrys that A.C. Spark Plug had the contracts under control, they arranged with the British Purchasing Commission in Washington to place further orders directly with A.C Spark Plug.

The twelve main sub- assemblies were manufactured by 12-15 sub-contractors of diverse backgrounds such as the manufacturers of pinball machines, cameras, typewriters, and thermostats. A high proportion of female labour was employed, reaching 80%. With so many diverse sub-contractors involved, careful inspection procedures had to be put in place by Sperry. In particular, inspection procedures had to ensure the correct alignment of the sub-assemblies prior to final assembly at the Flint Plant.

At the Flint plant, an assembly line was installed from incoming post inspection stores with a ‘line drop’ at each assembly station for fitting the scheduled assemblies.

The final testing of the completed units was carried out in five vacuum chambers approximately 900 x 1200x 900 mm. In these chambers could be simulated the bombing operation with climb, glide, air speed and cross wind direction. Shaft outputs for the sighting heads were also recorded. The bombsight was tested at 1000 ft levels to 20,000 ft.

The sighting head final test comprised mounting the head on an elevated platform to about 2.4 m above floor level. The input into the sighting head from the computer cabinet was simulated together with specified limits of roll. The performances of both sighting head and computer cabinets were checked to meet the specification. The figures were recorded on charts supplied with each computer cabinet. After final testing the finished computer cabinet or sighting head was mounted in a steel cabinet ready for dispatch.

In August 1943 Sperry published a technical manual describing in considerable detail the T1 bombsight which is now in the possession of the author. The manual recorded the design at that one point in time; when the gyros were air suction driven. In 1944, and from Serial No 18,000, Sperry electrically driven units replaced the air suction gyros. These were used in all succeeding developments of the T1.

The manual states that separate versions were produced were as follows;

1590649 Blenheim and Wellington

1593745 B 24D-Liberator

1593175 B25C & B 25D-Mitchell

In this early manual, apart from a line drawing of a single Lancaster there were no references to the Halifax, Lancaster, Manchester or Stirlings heavy bombers, yet these aircraft were to be the principal bombers of Bomber Command. There is a mystery surrounding this statement, as I am assured by George Krepps that A.C Spark Plug produced in August 1944 one model only of the bombsight. Thus technical centres in USA and UK would have set up the bombsight to suit the flying characteristics of aircraft designated to use it.

A final version of the bombsight was developed to cater for all aircraft that was designated to receive this instrument. A set of loose cams were added to each sight produced which included a dedicated cam for each type of aircraft to using the T1 bombsight. The dedicated cam automatically set into the bombsight the flying characteristics of the aircraft

No attempt was made to pair up a sighting head with a particular computer cabinet. These were to remain completely interchangeable with the corresponding British units as manufactured in Britain. In fact, an RAF bomber aircraft may well have had a T1 computer cabinet, operating quite effectively without loss of accuracy, with a Mk XlV sighting head or vice-versa.

An astonishing total of 23,450 T1 bomb sights were produced at the Michigan plant over the period of November 1942 until June/July 1945. When the factory was fully operational, the output reached about 54 completed bombsights per day, using two shifts of workers eight hours per day in a six day week.. From a pre-war figure of 5,000 employees at A.C. Spark Plug the total size of the operation grew to 20,000.

Further development of the MkXlV sight in Britain appears to have been based on the T1 series of bombsights rather than the British version. Towards the end of the war bomber aircraft were flying higher and so the bombsight design had to be modified to allow for this change. In December 1944 the T1A and B versions were produced. These bombsights had a similar speed range but the effective height range was increased to 25,000 ft.The maximum climb the sight could measure had been increased from 5° to 11° and 12° respectively for yet another version. The T2 and T4 sights were developed and manufactured in Britain after the war for later aircraft and often installed in conjunction with radar devices. With the T2 the effective height range was increased to 600-25,000 ft, a speed range of 150-350 knots and a wind speed of 90 knots. The higher wind speed was to allow for the jet stream at greater heights.

It now seems that MkXlV was the name universally used by RAF and Commonwealth Air Bombers for the bomb sight and most were unaware of the T1 version. However, the version most readily found today in museums and in private collections will be that of the T1 and its derivatives.

During the time the contract was executed it appears there was no record of a visit to the factory by RAF representatives to demonstrate the considerable operational value of the T1 to the Allied War effort. This was an omission that was regrettable. However in August 1943 Mr George Mann visited the UK for a period of about a year liasing on behalf of A.C Spark Plug with RAE Farnborough, Boscombe Down, and the Ministry of Aircraft Production. He also toured unnamed British factories manufacturing MkXlV bombsights.

When the contracts were completed George Krepps continued his association in 1953 with bombsights by working on the Bombing and Navigational Systems for the American B52 bomber.

The author would like to place on record his appreciation of Mr Geoge Krepps in providing extensive information in the manufacture of the T1 version of the bombsight in the USA and to Mr D.W. Allen in granting access to his unpublished autobiography notes on his part in the development of the Mk XlV bomb sight at RAE Farnborough in 1941

References:

AVIA15-122, AVIA15-123, D.W. Allen, Unpublished Biographical Notes

Details on Bombs and Mines

Major Bombsights Of WW2

By: Bruggen 130 - 7th August 2007 at 17:28

The main problem with these weapons was not the publicity value but their shortage. Harris said they used the bombs, “…… in hand to mouth …” and their availability was the problem. Notwithstanding the use of Tallboy et al by the British, Disney was used operationally by the USAAF and contemporary newspapers reported these facts.

“The first use of the 12,000 lb bomb was on the night of June 8-9, 1944 against the Saumur Railway Tunnel, a vital link for German reinforcements trying to get to the Normandy invasion beaches. 19 bombs were dropped- at least one from as little as 6,000 ft- blocking the tunnel with tons of rock that required weeks to clear.

Following this initial success, the production order for Tallboy was increased to 2,000 with half to be manufactured in the United States- some by the A.O.Smith Corporation of Milwaukee. Vickers Armstrong and the English Steel Corporation made up the bulk of U.K. production.” What must be added to this is the use of the Amrican produced T1 bombsight which was an exact copy of the MKxiva bombsight by Bomber Command. All operational bombs used by the USAAF and the RAF were interchangeable though the box tail on the 1000lb bomb had to be changed to a cylindrical type of which there was a great shortage.

Well, Is this T1 bomb sight another name for the SABS bomb sight that 617 used on the night of 8-9 June 44.

Regards Phil

By: chaza87 - 7th August 2007 at 17:05

US Use of Tallboy / Grand Slam…

The main problem with these weapons was not the publicity value but their shortage. Harris said they used the bombs, “…… in hand to mouth …” and their availability was the problem. Notwithstanding the use of Tallboy et al by the British, Disney was used operationally by the USAAF and contemporary newspapers reported these facts.

“The first use of the 12,000 lb bomb was on the night of June 8-9, 1944 against the Saumur Railway Tunnel, a vital link for German reinforcements trying to get to the Normandy invasion beaches. 19 bombs were dropped- at least one from as little as 6,000 ft- blocking the tunnel with tons of rock that required weeks to clear.

Following this initial success, the production order for Tallboy was increased to 2,000 with half to be manufactured in the United States- some by the A.O.Smith Corporation of Milwaukee. Vickers Armstrong and the English Steel Corporation made up the bulk of U.K. production.” What must be added to this is the use of the Amrican produced T1 bombsight which was an exact copy of the MKxiva bombsight by Bomber Command. All operational bombs used by the USAAF and the RAF were interchangeable though the box tail on the 1000lb bomb had to be changed to a cylindrical type of which there was a great shortage.

By: 12jaguar - 7th August 2007 at 13:29

Agreed, if the USAAF had been working ‘hand in glove’ on these designs, you’d have thought that they’d have been trying to integrate them on to their own aircraft long before 1945. They were never ones to miss out on the propaganda value of allied co-operation in developing new weaponry.

By: dhfan - 7th August 2007 at 13:17

How does USAAF installation trials in June 1945 prove they were a joint design when the RAF had been dropping Tallboy operationally for a year by that date?

By: chaza87 - 7th August 2007 at 12:44

US Use of Tallboy / Grand Slam…

I am sorry but I have to point out the final two sentences in my previous posting.

The point I was trying to make with the evidence that I researched was that these weapons should be regarded as joint Anglo American. It was as simple as that.When the test reports were filed copies went to the British and vice versa. Its as plain as that. None went to the USSR, France etc.

Even Tarzon, in American publications, is described as having a 12000lb British Talboy body and so it goes on.

And I do know from interviewing those present, that at the test of Highball around the sea lochs in the the west of Scotland American officers were present. The two nations worked hand in glove to produce these weapons and to make them effective

On 15 June 1945 a B29 was tested at Eglin Field with a British Tallboy and Grandslam for installation trials. The aircraft was 4263577, 6 reports on these trials went to the RAF The issue I am making is that the British worked hand in hand from 1940 with the Americans to produce specialist weapons such as the spherical mine/torpedo and the deep penetration bombs etc

By: Eddie - 7th August 2007 at 01:07

http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=GB937959&F=0&QPN=GB937959

The UK patent for the bouncing bomb release mechanism – filed on August 11th 1942. What is the specific date on your drawing?

Also, August 1942 was when the scheme was presented by Wallis to the Ministry of Aircraft Production.

By: chaza87 - 6th August 2007 at 22:46

US Use of Tallboy / Grand Slam…

I am deeply grateful for your reply because it has given me time to sit with the drawings and compare their properties including dates. The American drawing is before the British one and is dated August 1942, I refer to 104 above which is correct. The American one is for a torpedo, “..an explosive container having an accss of symmetry etc” The design is like the Vickers design and it stipulates ” enclosed by a pair of hinged arms ….to rotate the container ….”. The drawing is identical in many ways to the British mine but very simple. And yes they are generic because they are the roots and branches of the later types which was correctly stipulated above would be different with production.

It is to be used by, “..the Government or one of its agencies..”

I am sorry but it now looks to me like the rotating mine was ever more an Anglo American project.

I hope you understand that I would be breaching copyright and confidentiality by publishing the drawings without permission. I am only laying the facts.

By: Creaking Door - 6th August 2007 at 22:00

The mines are given different names in America and in the UK/Europe.

I doubt very much ‘Upkeep’ was called anything in ‘Europe’ before the night of May 16th 1943!

You are correct that the American design is only a few days later…

…it also has a different name on the drawing but it is an American official agency that claimed the design.

What was the American ‘Upkeep’ called?

What was the American ‘official agency’ that produced the drawings and ‘claimed the design’ and, most importantly, what dates are on the drawings?

I still maintain that these drawings are almost certainly copies of Upkeep drawings intended for production of Upkeep in American factories (and possibly to assist mounting Upkeep on American aircraft).

By: chaza87 - 6th August 2007 at 16:44

US Use of Tallboy / Grand Slam…

The mines are given different names in America and in the UK/Europe. You are correct that the American design is only a few days later, it also has a different name on the drawing but it is an American official agency that claimed the design. Whereas in the UK its Wallis and Vickers Amrmstrong etc, a private company who are credited with the design.

The main problem with casting these bombs was to maintain a uniform strength throughout the case. This was what Harken and Ruby set out to prove. The Americans and sometimes the British tended to forget that these weapons were not intended to direct hit but in fact to miss and cause an earthquake effect. I understand that it was this effect that capsised the Tirpitz. A direct hit was no use.

The first American welded bombs were unstable due to the lack of turning inside the case, slag was left and the bomb had a tendency to break at the welds. This was later rectified.

In Harken it was found that to stop a bomb breaking up an altitude of 35000 ft, which was the absolute height for dropping, produced the best results. but this was for the model of the 12000lb Disney bomb dropped on Farge. These were dropped from B29 4521751, The A/c was Captain Willis Boyde, the British had no aircraft at that time which could carry out the test

The American phase of Harken dropped Amazon and Samson deep penetration bombs. These were the children of Tallboy. These bombs were dropped from the same aircraft that dropped the 1650lb model Disney.The date for Harken was 29 August 1947. Amazon had a tendency to break up on the penetrating the roof, the weakness was the rear weld. Samson was akin to the Tallboy/Grandslam family in shape, but the T26E2 Samson was longer and slimmer it was about 195″ long. The release altitude for both these weapons in Harken was 17000′. The Americans then pursued the the 44000lb bomb which had been cast in 1946 to a wave of publicity then slipped into secrecy. There are pictures of a 44000lb bomb being carried by a 29 but no-one has said that it actually flew with the bomb. It is strongly possible that the take-off shots of the 29 with the 44000lb bomb show it carrying a model.

The B36 could cary at least one 44000lb bomb or two Tallboy/Samson/Amazon/Grandslam bombs

By: Creaking Door - 6th August 2007 at 02:39

Right, you’ve completely lost me now.

Generic drawings are the drawings on which the British and Americans based the Upkeep weapons. They are published officially in America, Britain and Europe and on the net.

These weapons are joint Anglo American, the interst is 60/40 for each nation.

According to your earlier posts:

All these weapons can be considered as joint Anglo American. The drawings of the American spherical mine and the British spherical mine are only days apart.

Yes we are indeed talking about Upkeep and its family and the generic drawings.

Given that there was only one ‘Upkeep’ and the British and American drawings were only days apart might I suggest that the American drawings were copies of the British drawings intended for production of Upkeep in America?

There is a big difference between the design of Upkeep and the production of Upkeep.

Again with regard to Tallboy and Grand Slam are we talking about the design or the production of these weapons?

Evidently the design of the casings of these weapons was changed (from cast to welded) to aid production in America (and the integrity of the welded casings was proven) but the integrity of the original cast casings had also been proven (as had their accuracy with offset tails) in trials and more importantly in combat.

I don’t doubt that America spent huge sums of money on Tallboy and Grand Slam but it is important when and how this money was spent. Money spent integrating Tallboy or Grand Slam with the B-29 in the summer of 1945 hardly warrants these weapons being thought of as joint Anglo-American.

The Ruby project that you mention was a joint Anglo-American project but this was a test drop of Tallboy and Grand Slam carried out in 1946.

By: dhfan - 6th August 2007 at 02:38

After much Googling, it appears Barnes Wallis patented the “bouncing bomb” on the 11th of August 1942.

Obviously an American design then…

Loads of info about Tallboy, Grand Slam and the American revisions here:

http://members.aol.com/nukeinfo2/

Thanks go to somebody who posted the link on WIX a while back.

By: chaza87 - 5th August 2007 at 17:05

US Use of Tallboy / Grand Slam…

Generic drawings are the drawings on which the British and Americans based the Upkeep weapons. They are published officially in America, Britain and Europe and on the net.The offset American tail is there and they are covered by the Patent interchange Agreement. If you do not go to published official references which lead you on to true research then statements can be very weak. I cannot believe how many people have not read the books or searched the achive I listed and are not included in Bibliographies of popular history They do Frankland, a former Bomber Command officer et al a great disservice, these writers had free access to all the files.

Everything is there such as the reports on Harken and Ruby, its the hard slog, go and see, I have seen them. Until someone comes up with different hypothesis then I stick to what I have said

These weapons are joint Anglo American, the interst is 60/40 for each nation.

Tallboy was turned down and flew in a Vickers Valiant as a 10000lb bomb, a prototype for a British nuclear device, Air International covered the development some years back.

Again from an official publication, Kurt was developed at the German Air Force experimental center (E-Stelle) at Travemunde.It had a 30 inch sphere weighing 400-450 kg. Its range was about 400 meters. To increase its range to 4000 meters a rocket device was added but trials were stopped in August 1944. The rocket Kurt had an air tail preset at an angle of 10 degrees and to maintain stability a gyroscope was installed. The explosive in the sphere was cast and contained two fuzes which replaced the type 50 fuse. The drawings of Kurt are very pretty

By: mike currill - 5th August 2007 at 12:09

That clears up my confusion on that matter then. I blame it on the grey matter not being what it once was if it ever was.