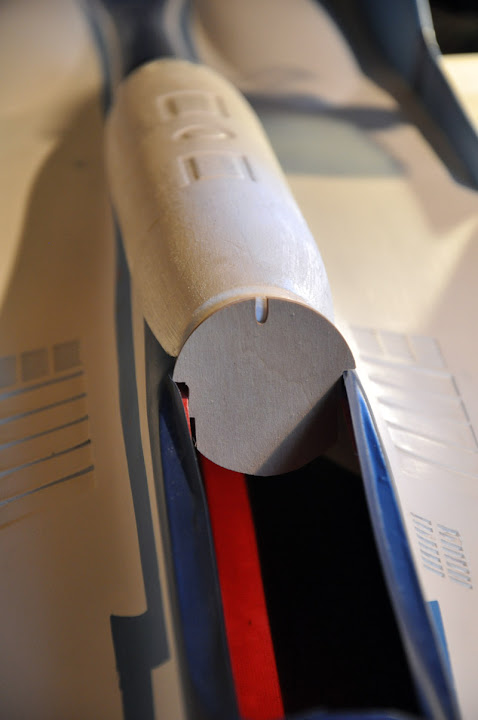

The dorsal,

making is still going strong at the moment.

Was looking around in my old wood junk box I have around

and found from older kit a remain parts that as fit my need

about the joining of the canopy and the dorsal foam part.

Sometime we find stuff that fit perfectly are expectation on a particular

way a part should be done. That one was already done the way I need it to be with the right cutting at the right place.

So I got this joining canopy foamy dorsal together for a test fit.

Wow, it fit like a glove ball, like if it was made for that in there.

In betwen and behind that round woody part I will add

a kind of black material that is very lite as weigh and strong and

will join in betwen the foam dorsal part and the canopy.

I also gone be using that white & black material that is lite as weigh too

and will re-enforce some specific area in the fuse to keep all fuse weak structure strong and to not have any Vibration in fuse.

Now back to work on the dorsal and in the fuse for re-enforce process …

Getting

there I see Jenna …

What is on the menu build list next ?

What will be the covering you’ll use to acheive?

Looking good as clean …

keep the good work and keep us feed in on your project …

I’m following …

Yeah,

thanks to have clarify this issue with me … lol …

Nah, I knew all the time you guy’s were around watching secretly … lol …

Now on the MIG 29 SMT version type class,

Wednesday,

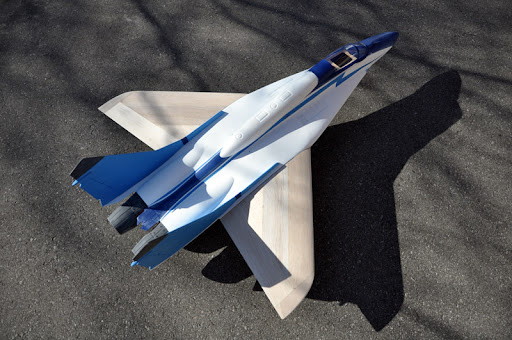

Got the MIG outside the home for a dust cleaning …

Coming along fine on the dorsal making. Will work a little more on that and

some other parts of the MIG till my electronic’s flying system’s get’s here …

Will place a order this week at my hobbyshop for:

HET EDF fan unit 6904 (3.17mm adaptor)

http://www.highendrc.com/index_eproduct_view.php?products_id=20

AR8000 8-Channel DSMX Receiver by Spektrum

http://www.horizonhobby.com/Products/Default.aspx?ProdID=SPMAR8000

Aileron’s servo’s:

82MG Micro Servo by Hitec RCD Inc

http://www.horizonhobby.com/Products/Default.aspx?ProdID=HRC32082S

NAV lights system:

V3 LITE RC Lighting systems

http://www.lazertoyz.com/shop/RCLights.htm

The MIG 29 Fulcrum SMT dusting off ON TARMAC:

Also,

while I was sanding her down to the bone, did the “Crack test”.

It did crack at a fiew area and no major issues on that test but it

got out some magnets off there location on the fan cover on the tail.

So will re-glue them on and will continue the process making.

I have to make the canopy fit great on the dorsal SMT replica part.

So slow is the key and think ahaead and imagination is use at best.

For now, I wont do the RG on the MIG, as it will gain some extra weight.

Will keep it low weight as possible and will be happy if I can get it under

7 lbs. The color schemes are still not confirm as yet, but getting my

ideas together more and more it approach the primer time application …

Thanks for the interest you have shown me here with the MIG 29 Fulcrum SMT class type making …

I feel at home with the UK friends here for shure …

Ladies too yea know ! 😀

More have,

been done on the dorsal making of the SMT MIG 29 version type class.

To make a perfect fit of the dorsal unit part, I have laydown a sand paper #80

on the dorsal of the MIG. Then took the foamy dorsal part and did some foward and backward action pass to sanddown the foam to become later as a perfect attach join fit via the top fuse dorsal of the MIG and the foamy part of the dorsal SMT class type.

Till now it as come to a nice align fit. But more sanding and more fitting are to come as to make the canopy fit equaly to the dorsal new part.

I will keep this process simple and will re-produce as close as scale this unit dorsal part. Will gain little weight as the foam is empty inside so that gives me less weight at final acheivment.

I shure love the beefy style it gives the MIG as look now with the SMT dorsal making …

Please till now …

More to come and to show process soon …

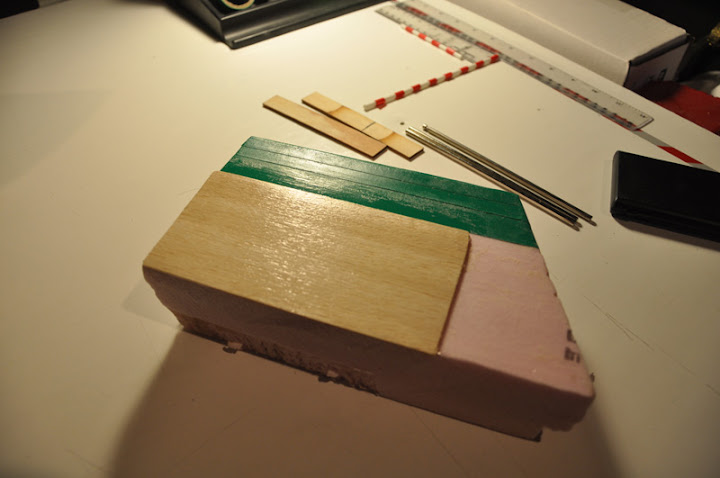

Now,

was yesterday testing the wing covering glassing on a piece

of balsa sheet test part. As mention befort I have made the use

of some hair spray MEGA hold product and made a 2 coats pass then

let it dry 20 min’s in betwen coats.

That action the balsa sheet wont suck in the glassing product use.

Befort the next step I needed to sand down a little the balsa wood sheet.

Next was to apply floor varnish with a small brush on the balsa sheet wood.

Did one pass coat and let it dry 12 hours. Then second coat was apply till dry.

Little was apply and brush it till flush and silk. Don’t over do it at this stage …

Look amazing as glassing goes and finish. This week end will test the first coat

of primer on the balsa sheet wood tester. Will come back with the result soon.

Also I have done a little on the elevator’s and start to look at the dorsal shape

of the SMT version MIG 29 Fulcrum to be done in proper size and shape.

The dorsal of the SMT version making.

Will see how it turn out befort inplant on.

At present,

Testing stage on the MIG 29 Fulcrum SMT dorsal version type style.

Love the beefy look of the dorsal on the SMT …

More modification are to come on that area section of the MIG.

After,

taking all off the mono covering over the wings that had air bubbles all over,

I have sand down both side wings till a complet clean and smooth surface.

Now the wings are ready for the next step …

Having aileron’s cutting & inplant & followed by a 2x servo’s build structures underwings location.

Retractable gears holddown wood structure to be build for main and nose gears that will be going into the fuse soon …

Found something to add maybe later at that location inplant …

Will see about that later …

Very nice,

doing and projects Jenna …

That is really something else what you do …

Keep us feed in on your doing with those projects at hand …

Cheers Mate !!

Have a great year 2011 …

Yesterday,

got to the wings and to off the covering.

Did some sand down on them bottom and top wings section.

More to come on the wings to do soon …

Next will be to make all my RG wood support that will attach the

retractable mechanical air system.

Saturday,

again on the sanding process outside at the sun all afternoon.

Finish the third pass on the fuse with sanding lite paper process.

It look very clean, smooth and ready for primer soon.

Then got back ont he vertical rudder fin’s.

Was to sand down with lite sand paper. Finish that at the end of the day

and result looks awesome and ready for primer soon.

Now I have found 2x small Hitec HS81 servo’s that i had from a past kit.

They are brand new from the box and will inplant them in the rudder’s

vertical fin’s interior side to activate rudder fonction soon.

Will look at the wing’s today …

Yesterday afternoon,

got to sand-down the vertical rudder fin’s.

The ruff sanding as been done and remain to do is

to sand-down with a smoother liter sand paper today to finish them ready.

Was very windy outside yesterday and it help blowing the dust over my part’s

I was sanding down. I Also when over the fuse and sand down with a liter sand paper to finish the fuse sanding …

Been having thought’s about the color scheme design I will do.

At the moment I have some great idea’s and think I found what will be at the paint job menu later.

Time will tell …

Some up-date …

Been reading alote about this model kit on some build thread.

Some fly it lite and some fly it heavy like 9lbs … Ouff …

Great model for shure if kept very lite. So got on the move in someway

and stripe her down to the bone … Kept the top dorsal red color and front nose black and greay silver nose cone.

Sanding,sanding,sanding as been on my schedule days lately.

MIG 29 on the sanding down to the bone process:

Dusting off a little and more sanding to come …

Will attack today the twin tunel underbelly sanding process …

The MIG Journey as start !

First I have set some re-enforce with the Automative glue for the EDF hatch door’s. As most of time model made of fiberglass have some dry area that need to be re-freash. Do this if your feel and hear craking sound while handle the fiberglass part’s.

Now they dont crack sound while handle anymore …

You wont be sorry later to do that process …

Next to come is to re-enforce all in there and where it need automative glue to freash it up

and bond well all those fiber that join together ….

It maybe not much fun now to do this, but worth the effort to a lasting flying MIG 29 jet in my collection.

The MIG 29 Fulcrum

as a special type class I want to re-produce.

As far as today here is the,

MIG 29 Fulcrum SMT class type I am looking for to reproduce in scale soon

and will base my self on the SMT class type detail’s and part’s to make.

I do not have my mind set on the color scheme as yet …

The MIG 29 Fulcrum is on her way to my homebase now.

Should arrive this week if all goes as plan …

The MIG 29 Fulcrum SMT class type:

The last fiew,

weeks have been kind of busy but back on the routine

with the Mitchell now …

To come,

will be to cut the retractable main gears door’s bay from under

left and right nacelle. I have align the cutting area with tape.

One of the nacelle seem a little off align from carves line already done from the factory. Will see to cut on the right alignment route so the strut get’s in straight into the retract bay area.

Only one seem off ,, so will make shure to cut it where it will do a great job even if I have to be off the already mark carves lines to follow from factory … Little ajustment at time with ARF …

Will take my time and all should fit smoothly …

Yea I will take my time no rush how so ever need to be perfect.

Little by little I’ll cut the door’s so it come to my satisfaction result.

Bay door’s cutting area on nacelles:

Greatly done …

Nice paint sheme also showing,, very pretty …