Oi! can i have my vulcan engineer back yet, he has an aircraft OOP here needs fixing lol.

Ahh, to be in demand :rolleyes:.

Sorry I’ve not been up much, however things have been moving in the background for 319. Working towards getting the wheels, chemicals and hopefully rivets (blue_2, you’re committed now ;)) we’ll need to get her ready for the repaint (whilst bumping Lindy back to the top of the thread).

20th June update

The engineering team had another good weekend, with a good turnout and lots of jobs getting “done”.

First the Victor, Nimrod and buccaneer were all given their monthly engine runs with various systems exercised, the first time the Nimrod has been run at YAM.

Cockpit of the Nimrod, Steve Pepper at the helm, Victor Sim flight engineering and Blue 2 in the co-pilot’s seat.

All engines turning

Crew chiefs and ground power unit

Getting ready in the Victor cockpit (victor internal shots by Blue_2)

All four turning

The AEO (Rick) at work

All this was watched over by the museum’s volunteer firemen, quite a few of them, with the pathfinder out of shot.

After the fun was over and the aircraft put back to bed work continued on the RAT scoop whilst another team tried to address the power issue mentioned last week (this was an issue with the electric power from the APU and so did prevent an engine run).

New seals were fitted to the RAT ram hydraulic union and these seem to have fixed the leak.

Blue_2 brought along his riveter and fixed a loose guard for the elevator control rods that had previously been hidden behind ducting.

The inside of the RAT received a second coat of paint whilst after lots of measuring and rubbing Nick managed to cut and sand down a new brush to fit the alternator.

Once dry the RAT will finally be ready for refitting. The fault that started the whole RAT episode, the micro-switches in the centre. With new seals fitted the current switches should last for a good time yet.

By 5 o’clock the other team hadn’t managed to get to the bottom of the APU electric fault but were still hard at it.

Finally a quick (partial) victor team photo.

I’m not sure if this is of any help, but I know there are two or three held in “reserve” at the Polish air force museum at Krakow (or at least kept behind some sheds), as well as another three or so out on display. They might be able to point you in the right direction.

You’d probably need a fungicide to get the lichen off properly.

Thanks for the suggestion. Can you recommend any in particular?

You can also follow the engineering updates elsewhere on this forum;

http://forum.keypublishing.co.uk/showthread.php?t=78402&page=8

Guys, the name of this thread has been edited to cover the restoration and updates of the NEAM Vulcan. Hopefully someone will be along shortly to provide an update on the repairs to XL319

Thank you Peter, and here’s an update;

It was quite quiet on Saturday so I decided to have a go at washing her. I’m not sure when she was last washed but some areas were thick in lichen.

Before, note the streak marks underneath and small patches of lichen on top, particularly on the green (did that have different chemicals in to the grey?)

After an hour or so of using a bucket and sponge one of these turned up.

Apparently the keeper of this green goddess used to wash XL319 when he was a fireman at Sunderland airport with a very similar engine. Here his son takes over the task.

This greatly sped up the process (thanks)

Unfortunately the lichen proved too tough for even the green goddess to blow off, so it was back to the bucket and sponge (though an angle grinder may have been more appropriate!). A few more hours of scrubbing and a small part was gleaming and lichen free.

The stubbornness of the lichen meant there wasn’t any time for proper engineering, the flying control motors will have to wait for another week.

Also, if anyone has any leads for cheap rivets (a mixture of blind and standard, all countersunk, excuse my lack of correct terminology) and aluminium sheeting we should soon be needing a few to tackle the control surfaces.

Finally one for all the closet botanists on here, I’ve been told this is a marsh orchid, growing up through the old RAF Usworth tennis court.

Chipper in!

Steve (Sven) will be along presently with the more technical update. After his Pie Sarnie that is…

Oi!!

There’s not really much to add. Worked continued on a number of fronts, some more successfully than others.

The scoop and intake pipe is now connected, but the RAT needs a little more work done. Today saw it being repainted and the brush springs mildly de-corroded, during which we discovered that one of the brushes had become stuck. We may now need a new brush, if anyone has any leads they would be much appreciated (I’m afraid I don’t have the part numbers to hand).

The system isn’t ever used by us (only needed in the event of a full engine failure and it only works above a hundred or so knots), but we always strive to keep it as original and operational as possible.

The RAT scoop ram was tested for leaks, using the hand pump due to the aforementioned power issue. Nick seen here getting to the manual hydraulic pump (the only photograph I managed to take during the day);

This revealed the need for a new seal on the union which will be fitted next week. Patches of dry hydraulic fluid suggest that this was a problem earlier, but hidden behind the RAT.

Once that’s been replaced we can get on with putting everything else back in, including the chipper.

Our electrical team spent the day dealing with the power issue, though they’re not quite there yet the job seems well in hand.

thats because you left us to play with other peoples aircraft steve 🙁

you in NEAM tomorrow?

Fair point. Yes I should be down on the Saturday. Might have a go at giving her a wash if the weather’s up to it. Then carry on trying to get at the PFCUs to level the flying controls.

Will you lot be around?

Good to see the new thread going. I’ll try to get some Vulcan shots up soon.

Why is the Vulcan on a separate thread, surely it’s just an aircraft like all the others there:confused:

Looking forward to seeing some updates on WJ639;)

Ooh, how dare you accuse the Vulcan of being “just another aeroplane”. 😀 In fairness the current pace of work doesn’t necessitate a separate thread.

Steve owes me 7p- have you not wondered why he’s been very quiet recently…..?!)

I was hoping you’d forget about that. I had big plans for that 7p!

Glad to hear work’s going well and hope to come along to lend a hand next week.

16th May

Another week and yet another new face. The forum’s Bennyboy came along to lend a hand. The new members almost outnumbered the old this week. Work continued on the RAT scoops;

The new seals, still sealed in their original boxes.

Graham (Blue_2) fits the new seal (at last) whilst Nick prepares the surface for a fresh coat of paint.

Rich takes a turn

as does Bennyboy

Meanwhile the corrosion inside the RAT itself was removed with wet and dry paper ready for its repaint. I’m afraid I didn’t take a photo of the RAT, only the piles of aluminium oxide dust removed.

By mid afternoon the new seals were in and bare metal primed ready for going hemp next week.

In parallel with this another team were busy working on removing corrosion from the trailing edge of the flaps, no photos I’m afraid but progress was made.

After last week’s Battle group North show the nimrod has returned facing in a new direction.

Something I forgot in my original post:

A broom handle is handy for ‘adjusting’ the chipper when in place. Push it through the intake into the chipper and lever it carefully until it fits correctly.Cheers

Rob

Thanks again for that, it’s surprising what on a Victor needs a broom handle to do right. Were they standard equipment on the squadrons?

Take great care when you fit the chipper back in (duct, vane assembly on the front of the RAT).

Fit the clamp snug, but not tight. Line the chipper up in the scoop and close slowly by hand to ensure that it lines up correctly. Tighten the clamp and check again by hand. The hydraulics are more than capable of wrecking the chipper. It’s not a thing you should rush.

The photo’s brought back some memories though.

Cheers,Rob

Thanks for that Robert. We’ll take extra care when putting it back in.

Update, 2nd May

Another good turn out this week with yet another new face, the forum’s own Blue_2.

Work continued on removing the RAT scoop to replace the seals. On close inspection it looks like there haven’t been any seals in since it left the RAF. They must have worked on that scoop towards the end of her service and not bothered to replace them.

The new engineer earned his keep by betting those last few stubborn screws out, allowing us to remove the top of the scoops.

Next the spring jack keeping the scoop open was removed. We then needed a wedge to give the person below room to work

We then took it in turns to wrestle with the split pins and bolts holding the scoop to the airframe. Meanwhile Ollie did sterling work keeping the scoop from falling on our heads, throughout a heavy downpour.

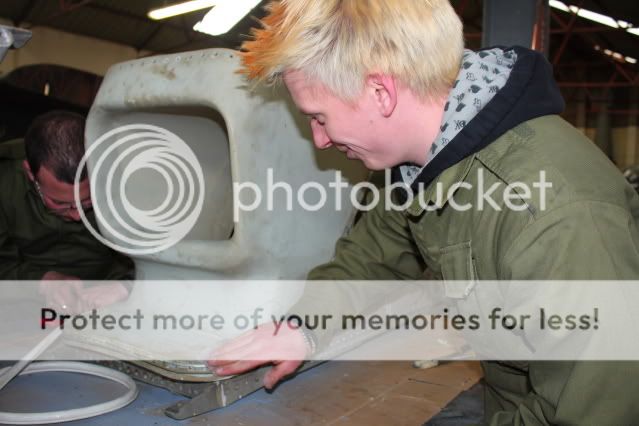

Blue 2 getting stuck in

Then after six hours of work we finally had it off, ready to join the RAT in the workshop for some conservation.

The hole left in the top of the fuselage was plugged by the scoop lid, firmly gaffa taped in place.

The team packing up at the end of the day.

Now we just need to get all it back in.

One of those much detested jobs but essential to her long term well being. Well done!

Thanks Paul. It is indeed. Hopefully it will stop the weather getting in and let the bits last as long as they have on the other side (at least 18years with no sign of degradation).