A few more photos from the museum shop…….

New nose glazing to replace the not so “optically clear” glazing currently fitted to the aircraft and an end view of rear turret ammunition ducting.

Cheers,

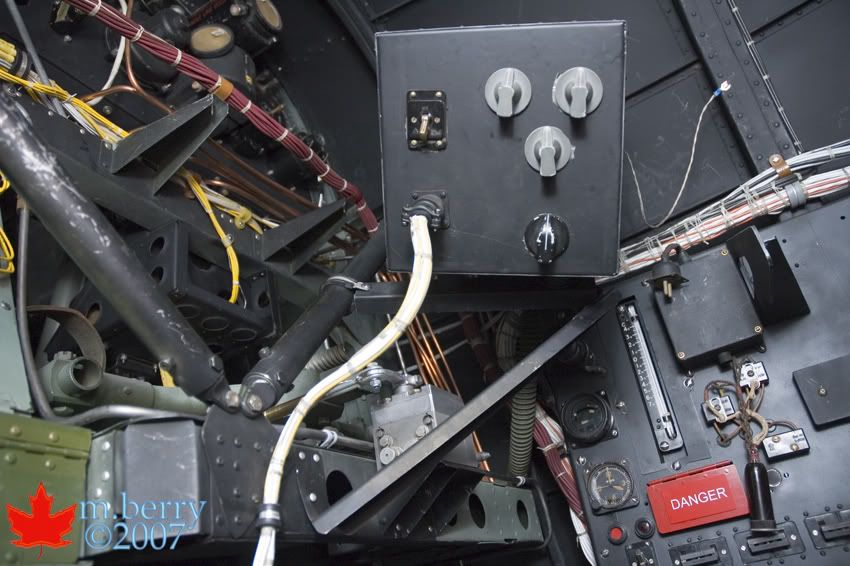

Last week I was fortunate to have another chance to tour through NA337. It’s still very much a work in progress.

I hope no one minds if I post a few more photos……..

Thanks again Deryck!

Morning all,

In repsonse to some comments in other threads about the progress of the Stirling Project, here are some latest pictures (hopefully) of our FN5 nose turret. It’s not quite complete as the port quarterlight cracked 1/2 an hour after carefully tightening the last screw…I nearly cried!! This resulted in a re-design of the mould and delay in getting it made.

regards

John

Reply With Quote

Nice work!

How did you construct your mold?

Are the hydraulic lines new and are those types of fittings still available?

Regards,

More here:

John, do you know the weight of the aluminum turret shell?

Are you now collecting pop cans?

For the last several years I’ve been trying to restore a Sperry lower ball turret in my basement. I have most of the internal parts except for some minor bits and a missing azimuth gearbox. The frustrating part is trying to find those shell pieces which were melted down after the war for their aluminum. I have some scrap shell pieces which are bent and broken, an ammo can door, as well as the armoured seat assembly but that’s about it for shell pieces.

John

John,

Does the sight of old aluminum pots at yard sales ever upset you?

Nice find Flyernzl!

Please don’t apologize for the condition!

Thanks Steven,

I was originally thinking of silkscreening, but wasn’t sure.

The texture of the top is smooth, the lettering may be very lightly engraved on the reverse side. It’s hard to determine because the original that I have been working from is still mounted on another turret.

I would like to try and have the graduations & lettering lightly cut into clear plastic and apply a coloured finish on the reverse. I’m not sure if the colour would show through clearly in the machined areas. It’s definitely worth a try.

If not, I’ll try a lamacoid.

Cheers,

Nice shots!

Do you have any pictures flyernzl?

Any project updates?

Made by Semco Instruments Leaside Ontario (Toronto).