Terrific video Mauld!

Thanks to all the other contributors to this thread as well. 🙂

Outstanding photos as usual DCW!

The EE Wren ‘undressed’ is an interesting shot; it really is a light weight in construction.

Thanks again for posting! 🙂

One mustn’t forget the the large numbers for Gipsy Majors produced by General Motors Holden for use in Tiger Moths or the reverse engineering of the 20mm Hispano cannons in very short order to be used in the CAC Boomerang.

Yes, Australia, once upon a time, had the capabilities to cast and manufacture complex aircraft components. The capabilities in Tasmania alone were astonishing. The Tasmanian Railway Workshop produced something like 15,000 Cheetah cylinder assemblies and the Launceston branch of what is now Repco produced hundreds of AS Genet Major cylinders. In fact the Repco workshop in Launceston was considered to be so good, that it was tasked with producing a large amount of precision tooling and measuring equipment for Australian manufacturer use.

Sadly, most of these capabilities have disappeared in Australia, to be off-shored to places like China.

Item 2 looks like a bilge pump.

Item 3 is a wobble pump/fuel filter assembly, usually found attached to the engine mount of one of the many NAA T-6 variants. 🙂

^^ Including the engine and instruments! 🙂

I so need to win the lotto….

Very nice! All I can tell you is it is a Fokker built D VII and not one of the license built machines from Albatros Flugzeugwerke or its subsidiary, Ostdeutsche Albatros Werke (OAW).

The guys over at The Aerodrome Forum may be of more help. 🙂

Looking good Dave! 🙂

Dear boys and girls,

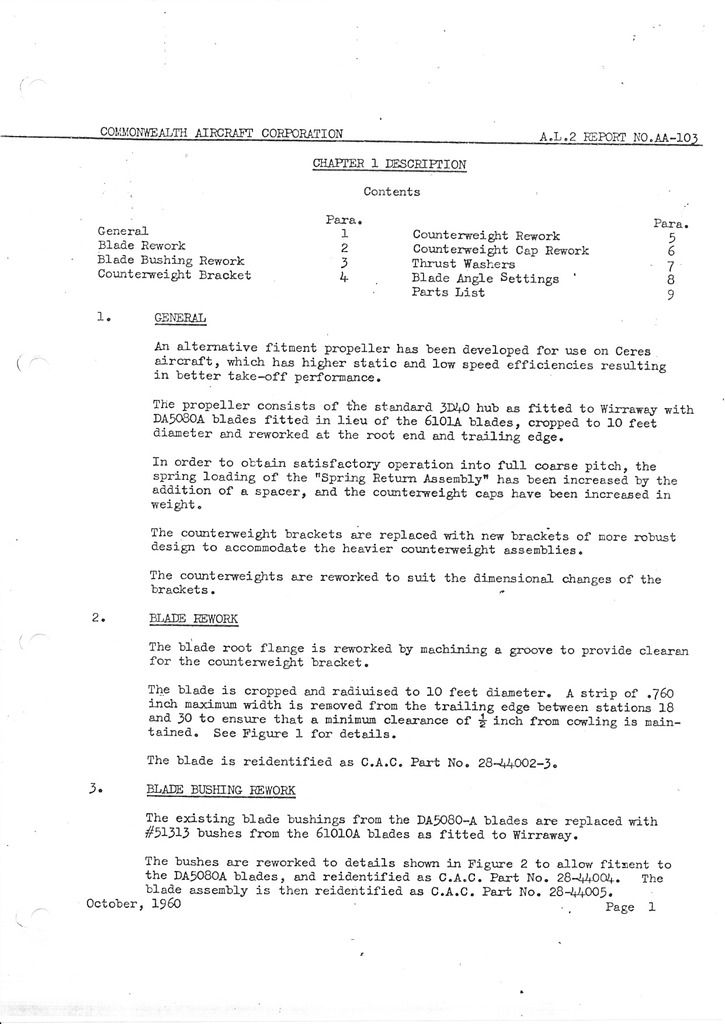

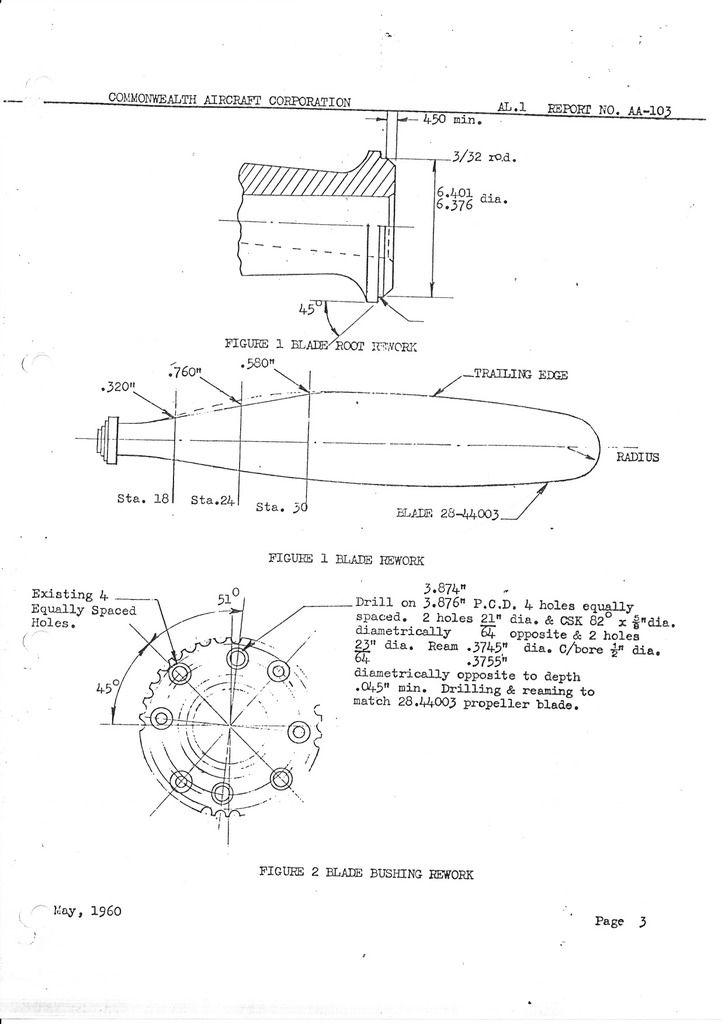

It is possible to rework hydromatic blades to use in counterweight propellers. This was done for the CAC CA-28 Ceres program, using Mustang blades, then Lincoln.

Please see the attached documents. 🙂

Definitely not Merlin or Griffon…

[ATTACH=CONFIG]235622[/ATTACH]

[ATTACH=CONFIG]235623[/ATTACH]

[ATTACH=CONFIG]235624[/ATTACH]

That arrangement means that there’s no valve overlap, right?

/Christer

There doesn’t appear to be any valve overlap in the DB601, but the DB605 cam lobe shape would suggest there is. Unfortunately, I do not have a DB605 manual – any donations would be gratefully accepted! 😀

More fantastic views into this engine. Thanks again, Matthias!

I would guess, based on the rather square shape of the cam lobes, that each lobe does double-duty with exhaust, then intake valves. Pretty slick design, and very clean looking. Again, as a newbie guess, I assume that square lobe shape allows a little valve lead, lag and overlap.

And it’s hard to tell, but it appears that there is no bearing material (like bronze) in the cam towers, where they hold the camshaft. The bearing material could be hidden inside, but if not, this is another fresh new surprise. This is why those high-resolution pictures are helpful, Matthias. Please, snap away !

Tom.

There are two cam lobes per cylinder, each lobe actuates an inlet valve (einlassventil) and an exhaust valve (auslassventil), therefore four valves per cylinder. I have attached a scan from my DB601 manual which should provide a clearer view of the mechanism. Please note the cam profile on the DB601 is not as ‘square’ as the DB605 – the DB605 has quite an abrupt opening and closing action, with a longer duration open than the DB601 and consequently, I believe, makes the DB605 sound like a race engine, especially at idle. 🙂

[ATTACH=CONFIG]235057[/ATTACH]

Fantastic photos Matthias! Thanks again for posting. 🙂 🙂

G’Day Paul,

I don’t have any pilot’s notes, but the sales brochure I have quotes 18,000 feet for the Cirrus Avian.

[ATTACH=CONFIG]234613[/ATTACH]

Best regards,

Paul

Santa lost an engine and I’ve got venison on the menu… :highly_amused:

[ATTACH=CONFIG]234154[/ATTACH]

It would look exceptionally good in one of my Avro Avians! 🙂